DJM3

-

Content Count

2 -

Joined

-

Last visited

Posts posted by DJM3

-

-

Hi all,

Was hoping to get some advise - I am elbow deep in a head gasket build on my M3 and was progressing through the cam install and timing.

this where where I think I made a boo boo.

on the “intake cam hub” I has everything fitted up and was aligned (2 bolts in the hub ) but they were not tight . I then proceeded to rotate the engine (by hand) and the locking bolts moved all the way to the end of the “slots”

My question is- have I now made valves kiss pistons ? Or is there a margin of safety with these “slots” on the hub?

sorry is that is not easy to flow !

adding a bit more content

The intake hub was assembled, 2x m8 bolts were securing it ( just not enough to stop the bolts sliding all the way to the end of the “slots”) so when I hand cranked, it all moved .

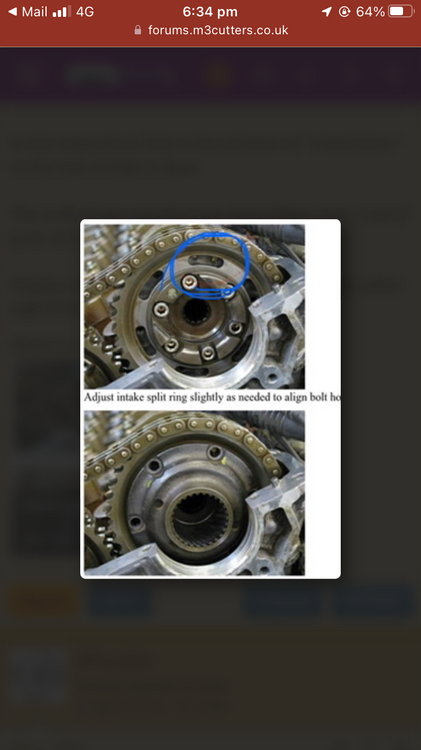

I added a picture -

In the top picture that is the amount of “movement “ in the hub circled in blue.

The bottom pic was the hub assembled- how I had it (just not tight enough)

Hoping that “that amount of movement “ was within safe limits !!!

S50B32 - Cam timing mistake

in Maintenance

Posted · Report reply

Hi Jon Dee, thanks for the reply - im now second guessing my memory - I dont know if it was because it was the first time i had hand cranked the engine in about 6 month or there was some slight resistance. But it did feel "tight" for that first rotation and after i redid things it was more free. . but again i could be all in my head.

Hi M3AN! Log time, Thanks for replying, I do feel much better hearing that now! Im just not sure why the valves are leaking air/ bubbling when i put solvent in the intake port and apply compressed air.

My engine builder did say there was 2 options for this

1. I bent or damaged the valve face

2. there is rust on the valve seat as the head has been in storage for 7 months before i put it on

I will be putting a scope in the bore on saturday anyway