Mador

-

Content Count

89 -

Joined

-

Last visited

Posts posted by Mador

-

-

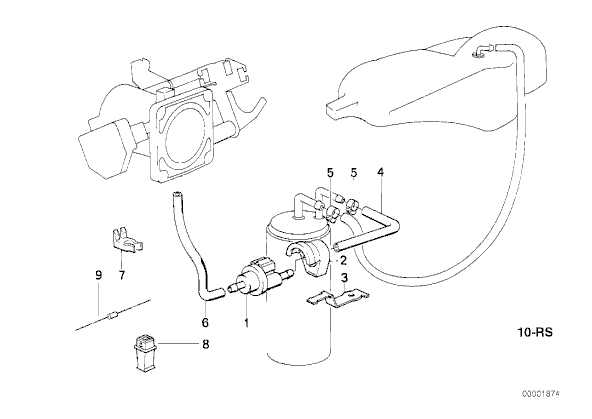

charcoal canistor valve. nothing to worry about, can leave disconnected.

dont understand what your trying to describe. got a picture?

pretty sure its part of the charcoal canistor setup. block it off if not using the charcoal canistor.

You mean that little reddish brown thing thats over by the front wheel/ LH headlight? I dont mind using it again, for now anyway as I think I know what you mean and will get that sorted thanks

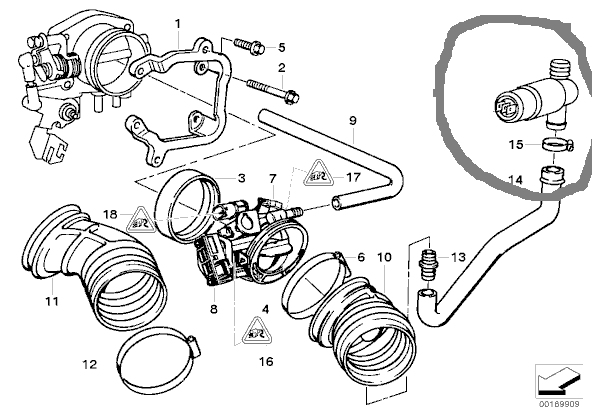

and I think it may be the idle control valve connection thats on the same loom as the MAF connection

-

Ive got the engine in the garage and have put most of the loom back together, and all the manifolds back on and what not, im stuck with a few things

Next to the MAF connector there is another smaller connector, whats this for?

Next to the MAF Intake Pipe to Throttle Body there is a small bolted in 2 piece hose tail connectors, what are they for?

Under the Throttle body there is a coolant in and out tail connectors, what is the third one for?

Thanks for your help!

-

Alright awesome ill stick with the MS, have found a wiring diagram for it too so that makes things easier, now just need to find a diagram for the M50 harness to wire it together, I see people wire the MS into the passenger floorwell, cant you just leave it in the stock ecu box? run a serial cable into the glovebox for the tune?

-

http://www.trademe.co.nz/motors/car-parts-...n-452310716.htm

Makes it sound easy, is it really that easy?

-

ah yes the trusty t88 go on put it on you know you want to

Yeah right I wish! doesnt look like theres much room between the exhaust and that stupid RHD steering

-

What are you using for tuning?

I have a standard ECU i put in this afternoon when I bolted the loom to the firewall, got carried away and tried to rush install before dark,

also have a megasquirt im gonna flip a coin to use or buy something tuners recognise :S no idea, i like to mess with things myself so thinking megasquirt

-

Yup common practice

but you will need to take some meat off the back of the flywheel

and use an e21 release bearing.

EDIT - beaten to it lol

alright so definately need to cut some of the flywheel off? alright, anyone know someone in CHch who will do this?

I have a Mill and a Lathe but wouldnt have a clue on balancing it?? if im right it needs to be perfectly balanced

-

Nice thread on it, glad to know it will work, have a spare getrag 260 aswell, but dont know wether to use the Getrag 240 or 260, I have all the mounts, and exhaust system even, to have it installed and running tomorrow, but will wait for turbo conversion

-

-

Last weekend I pulled an M20 engine out of my E34 that was like a slow whale..

I took this friday off (today) and drove to Temuka to pick up my complete M50, Got most of the Electrics installed properly with the rubber grommets and what not, but have run out of light and will get onto getting it installed tomorrow haha, will get pics up when i get a cam

No doubt will ask for a few hints on plugs and what not

Oh and I have a question, I left the Manual Getrag in place, will the flywheel and clutch fit the M50 from the M20? its a single mass or whatever flywheel

Thanks!

-

he said between the test drive and the dealer fitting towbar, Maybe he never got it home? May be the towbar setting it off? the actual tow bar protruding from the bumper - like you say though disable pdc

Nices cars too! Porsche!

-

The T3/T4 I have lying around ran 21psi in a 3sgte, should be able to get something of the same from 2 extra cylinders, see how it goes if it shits itself ill get a bigger one, just using what I have lying around

T88-34D is big on both sides

-

Originally was wanting to get a vanos engine, lower Comp with HG, Boost the hell out of it and control the Vanos through the megasquirt for "Cool" factor

Is Vanos controlled electronically, or some sort of mechanical regulator that opens to allow the high pressure oil feed to engage the Vanos?

edit: Great name by the way Ben

-

So you think I should scrap the idea all together?

Work wont let me use the laser to cut the copper, dont want to risk sending a 3 - 5k watt beam back into the machine due to the reflective properties of the copper

Would have to get it turret punched or choose a different material, but I dont want to risk spending alot of coin on a 3mm copper sheet just to find the punch rounds the edges of the cut and leaves nasty burs and tits

Just to understand your idea of using a Cam to lower compression, use a longer duration cam to allow the piston to follow the closing valve to release pressure out the exhaust? Or decrease the time the intake valve is open to allow less gasses in to compress?

Off topic, I have an E34 with M20b25 that has been through 2 heads, have now parked it up and am tracking down an M50 to turbo, have a garret T3/T4 and megasquirt sittin around and ability to fabricate almost anything at work and do the machining of the engine, you say you can get 20psi/500hp out of a complete stock unit as long as detonation is controlled through a tune? id be more than happy with less than 500hp

What would you suggest Crunchy since you have just completed or near completion of your build?

How much HP is your goal for what you have done to yours?

-

Awesome project, Im doing my own intake manifold aswell, did you make yours out of aluminium? I plan on mine being forward facing/front fed what made you stick to center fed? did you use original runners and cut off the plenum?

Keep it up!

-

glad you didnt have any problems with the B28 gear was cringing when I saw a post thinking I was going to be told it wouldnt work,

glad you didnt have any problems with the B28 gear was cringing when I saw a post thinking I was going to be told it wouldnt work,Gasket making process, I plan on buying a sheet of copper and using the laser to cut it to specs of oem gasket but at the thickness I choose of course, anneal it professionally in an oven, head and block machined flat and when it comes to install ive got a can or 2 of that spray on copper gasket stuff by CRC (shouldnt even need that though)

Heres a read if your interested in it

http://www.headgasket.com/faq.html

Also found this paragragh on a Nascar site

"Copper gaskets are popular with top fuel drag racers because the gaskets are available in a wide range of thicknesses, which can be changed to alter the compression ratio and "tune" the engine to changing track conditions. Different thicknesses can also be used to accommodate different piston and deck clearances. As a rule, every .010" change in the thickness of the head gasket will change the combustion chamber volume about 2.5 cc."

let me know if your interested in one as id have to buy a sheet anyway unless I can find an offcut big enough somewhere (but thats another hunt I havent started yet)

-

Thanks for the reply Pommy

Will keep you in mind but I think its "Too Good" as I will be stripping it down and building it and dont want to offend you by asking for it dirt cheap when its obviously had some money thrown into it that you would want back!

Cheers mate

Ben

I might be able to help? I'm thinking about selling my M50 Engine comp with Lume! and have spares and gaskets etc.

I bought to m50 my E30 the head gasket has gone, however has pretty much had every seal replaced!

sitting on a pallet shrink wrapped ready to go!

cheers.

-

Thanks will stay away from the Ali blocks then

Was hoping to get away with just the head gasket to lower compression and use B28 Crank and Pistons but havent looked into that yet as still acquiring an engine

and thanks for that page Glenn seems to do the trick! It suggests 3.25mm for a CR of 9:1

-

Im having to post here as I cant find anything in the search,

Does anyone have a chart or a formula to work out compression vs head gasket thickness?

for example: on an M50, 1mm H/G = 10.5:1 and a 3mm H/G = 9.0:1

am going to laser one out at work but want to know which thickness material I will need to get desired C/R

also anyone recommend what material I should use? I was thinking copper but a guy at work made one for his friend out of steel

Cheers

Ben

-

As title says

doesnt need to be going or complete

prefer high ks and cheap as its going to be built

Cheers

-

Really really nice, How is this coming along?

Im doing the same conversion but building an RB30DET atm for the E34,

Who did you go through to make the engine and gearbox mounts?

Im assuming theres no difference between RB engines in terms of mounting

Rough cost for it aswell?

-

Not following ya on how the idle made it stutter?

Didnt quite understand it myself,

probably starts the ICV working at lower RPM? So the ICV isnt starting to come on while your coming down through 1500rpm instead it comes into play about 1000rpm?

Did some research last night on the ICV and apparently people who have Deleted the ICV notice they can almost stall the car in 3rd and there is no stuttering - Improved throttle response and improved driveability at lack of Cold start and Cold idle, But fixed that with a manual choke type system to open TB partially when cold to have it idle high till hot

-

*Fixed* Thought id post the fix incase someone else finds they have this problem,

Stutter was caused by the idle being set too high

, Lowered it to about 650 - 700 and its once again smooth.

, Lowered it to about 650 - 700 and its once again smooth. -

Hey I have just moved to Christchurch from Gisborne,

Sadly havent found employment yet which is steering me away from going to a shop,

And its my only Vehicle aswell, but thumbs up to the public transport here its wicked!

And thanks for that input! Ill have to jack her up sometime and have a look into that, the Haynes manual says its

the Input shaft Bearing though, Ill give the heat shield a look and if its not that then I might aswell give the Getrag 260 a try,

Thanks for the help guys

Ben

1990 E34 M20 to M50 Turbo conversion

in Projects

Posted · Report reply

sweet thanks for that, the other guy said leave it - but im guessin BMW put it there for a reason so im gonna leave it alone to do its thing lol

I just looked at the ICV after work and ive already hooked it up to a cable that came from underneath the manifold that looked about right so Im still stuck with the cable that comes off the loom bout 60mm down from the MAF sensor

Id really take some pics but I havent got any batteries till Payday only takes lithiums alkies are dying at the flash lol

only takes lithiums alkies are dying at the flash lol