No name user

-

Content Count

1111 -

Joined

-

Last visited

-

Days Won

8

Posts posted by No name user

-

-

Run a pyro and 02 in each header, pretty common way to tune ITB's via a 2D map

-

These work a treat, i have countless customers using them from strip to drift.

Running through the turbo intake and running eth erodes the cooler out, meth and ally are not good friends.

Free Hp as such, but don't rely on it to cover DET get it tuned right without it, you should pick up easy 50+hp

https://www.ebay.com/itm/264980791794?epid=1559609774&hash=item3db21601f2:g:8iEAAOSwUmhf2~qI-

1

1

-

-

Really ?

adding overlap will limit high rpm power gain

-

I use Autronic in Oz drop them a message, or try Motorsport Electronics Nz

-

Sorry to hear of your personal issues i really hope all turns out well and im sure it will mate.

On other note regarding your cams the best thing to do is find the full cam specs and mainly the center lines and dial them in using that method, and fast and more accurate, find TDC with a dead stop then rest is straight forward.

Did the same when dumping the stupid VANOS off the V10, but i used a Cam Doctor on the cams to give me exact numbers thank fully i have 60 Deg in and 30 Deg ex of crank rotation so plenty to play with on the dyno, safe setting for you would be 108in and 115ex as a starting point being turbo.

-

1

1

-

-

Issue with either Hydro, petrol or electrics there still a massively high consumption of fossil fuels to build these vehicles.

I believe the highest consumption of oil goes into every day products as in plastics, roads and panels wiring,tires etc etc in vehicles let alone whats used for house hold goods and cell phones etc.

So regardless of how it runs there's no free lunches, we may reduce what vehicles use or don't but the fossil fuel will always be there to which i believe over 80% is used for every day products not vehicles.

We are polluting regardless what we do.

-

1

1

-

-

-

All good Allan don't hate ya everyone's entitled to there opinion, your not wrong about the gauges they are miles out.

Those who rely on the needle sitting in the middle really should check as you said cause by the time it moves up anymore it game over.

-

I guess we all have options like butt holes and prefer to see things how we want and take on board everything the manufacture said as gospel, bit like everyone believed the emissions thing with VW......yep.

My S85 V10 thermostat factory is 79 deg, kills the theory some have.

And we don't test older cars here for emissions and to complain about economy when you sit in traffic not moving for hours a day is counter productive.

-

2

2

-

-

I've don't this many times, had no change in economy and warm up time hasn't changed either.

Rather this than a cooked motor which they are well documented for doing.

Each to their own.

-

1

1

-

-

Warm upside from my understanding is there to assist the thermostat to open if it fails nothing more, but i could be wrong. The bypass system is used for rapid warm up and that i havent changed.

I also left the sensor part in the unit and plugged.

-

Yes im still alive, apologizes to a few

Kinda well over trying to help and inform due to the crap you get in return but thought this was worth a mention.

As many would know and ive learnt the hard way when you cook a M54 that equals dead engine and stripped head stud holes.

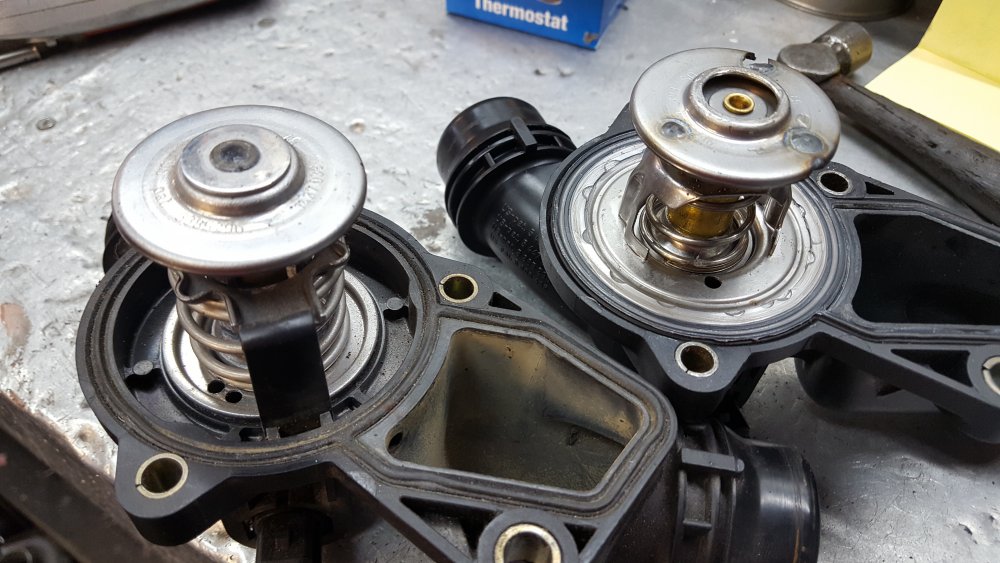

So ive done this a few times and works well and yes you could buy a lower temp one from VAC but hey wheres the fun in that, so for the DIY heres mine.

Remove the old setup and use a carbide burr to remove all high spots to give a uniform finish and dia hole, can be done if your savvy with a die grinder.

Once done purchase a thermostat as pictures, i remove the larger bottom plate from the old setup and open the center hole then a few spots of MIG its good to go and the correct install height ( yes i blew a small hole in it )

Now i understand not everyone has the gear i have but i turned up a ally ring to suit the housing and a step to match the new thermostat, i then peen the ally over to retain the new thermostat.

Next is use some silicone to retain it in place with a slight press fit, it can't go anywhere as once bolted up its retained, i also drill a small bleed hole to help bleed the system.

This is now set to 82 deg rather the 97 stock, some say its too cold but rather that than a new motor also your gauge wont show too much different but a scan tool shows another story.

PS: yes the V10 is done and in the hole and no i wont show progress or pics as well over the crap from the key board experts.

And those being OCD most welcome to correct my grammar

-

3

3

-

-

The gate pin wasnt too bad better than most i see, down side at some point itll rattle enough to be a issue then i re sleeve it

-

1

1

-

-

yep cant see a issue to do it, just use what caps you have and they can re tunnel to correct aliment clearances and youll be like new.

keep all caps in the order they came off if you can if not the engine shop will sort but pretty sure each one will be numbered

-

You can't mix and match cam caps, pull the carrier and get it re tunneled

-

It's a sin to cover those 8 trumpets with a air box

-

can if you like apart from cost its no bigger in size but at least its not plastic

-

Don't get me wrong its a lovely car, i just do shinny anymore if i got one would need to be well below average as i would rat rod it.

-

I have a very good contact who can land me a 635 with up to 180km on it for around 8-10k being a 4/5 star car, it too is left hook

-

Very nice car but...being left hook and auto that's a premium price being asked regardless the Km's

-

So, someone on here was trusting enough to let me do work for them, i know right ? ( one day you guys will get my humor )

Anyway, this wasn't a major upgrade just the comp wheel as turbine upgrade means using Chang made product and i refuse to touch them.

Comp wheel is MFS ( shinny ) 50mm inducer with increase radius and tip height,

Issues are they are so new very few parts can be obtained so i had to make the turbine rings as this needed oversizing as it had been leaking oil badly.

Holding the comp cover is a pain due to the outlet angle so a jig was needed, disappointing things are the stock built in blow valve the hole is way to small to be effective and the turbine wheel weighs a ton or at least shooting way about what it should be for its size.

End result a nice wee bolt in for those wanting a tad more without hurting drive ability and cost effect being well below 1k for my end at least.

-

9

9

-

-

3rd Nov is the first night wars , there is some winter meets but pretty pointless as no track prep

-

Boost means nothing its just a measurement of pressure or restriction has no reflection on mass airflow, as for end result ?

Let the motor decide, if you want really good numbers i can direct you to over inflated ego boosting dynos.

-

Depending on dyno ill guess 350-380kw wheel on eth closer to 500kw wheel

E85 fuel?

in Performance

Posted · Report reply

Meth inj