-

Content Count

364 -

Joined

-

Last visited

-

Days Won

1

Posts posted by central3

-

-

Any feedback on paint protection products. Specifically clear films versus spray on clear coat. I am looking at this http://www.chipprotection.co.nz/the-product/ . Seems like a good product??

-

1

1

-

-

I have owned this car for 3 years, in this time I have done 9,000km and spent 1,000 x more time working on it than driving it. I have got to the stage where I don't want to drive it for fear of dirtying it - haha.

Would love to see this go to a BS member, if you are interested we can talk a lower number than listed here. http://www.trademe.co.nz/motors/used-cars/bmw/auction-709337388.htm

-

1

1

-

-

Nice - pre face lift examples better than FL

-

After recieving the last parts required (graphite exhaust gaskets ex germany) I finally have her back on the road. Last shots of the refurbished underside. I am at last happy with the exhaust. Ist step last year was to replace the pipes in compartment 3 with straight through jobies - made very little difference. 2nd step was to remove the fiberglass packing in compartment 2 - slightly more noise under load but not much in it. Final step was to remove th fibreglass packing in section 1 - quite different now. Deeper note at idle and quite raucous after 3,000 rpm. No drone at highway speed and looks nice and stock.

-

Time waisting thread, their must be far more interesting things to talk two

-

Update - 10.3.14

Finally been getting on with repairing the chassis subframe mounting point cracks appearing. Drilled out and welded up the cracks, and installed the M3 reinforcement plates.

I also installed the RTA mounting reinforcements having noticed small cracks appearing in the forward weld.

This is just after welding and trimming. Currently sealing the metal work up with various paints and body sealers.

I also installed the rear sway bar reinforcement platesNice work. Are you doing this on a hoist?

-

1

1

-

-

Awesome work - what did Amit replace this with do you know?

-

I'm doing this to my E36 as we speak!

But god lord, that is so clean, quite unbelievably so!

Yes I have been watching you with interest - I would love to have a go at a rear mount brace as per your design, cool project - bit too much for mine though as I want to keep it pretty close to stock - absolutely appropriate for your machine though

Amazing work as per usual Paul. You should also note that you are a ticketed welder so this is NOT a backyard type repair.

I don't think anyone would hesitate to buy this car with all the attention to detail you pay to each and every time you work on this car.

p.s. Where did you get the rear axle carrier from? Is it a brand specific unit or a generic one that you purchased??

p.s.s Love the home made epoxy applicator gun/drill!!! (you should hire it out to BMW or better still, mass produce it and sell it on m3forums : P)

I do have one question however - how come you didn't make the LHR reinforcement plate larger so that it boxed in the repaired crack?

Cheers Tom and thanks for your advise leading up to this work - the diff carrier is homemade but semi-modelled off that which Reddish Motorsport use - don't think I will be hiring or manufacturing tools (fully available to bona fide BS members though). I did not plate over the crack repair as a good weld with reinforcement (i.e. the weld cap) is I think better than a ground down weld with plating (especially when working with sheetmetal I think). Also because the crack is at a shape transition point it would be hard to get a perfect/tight fit - for best strength the epoxy joint needs to be thin. When do we do the CSL?

-

I have been in 2 minds as to whether I should post my experience with the dreaded E46 M3 chassis crack, on one hand it is negative for resale purposes while on the other it is potentially good information for fellow Bimmersporters and I reckon the repair is up to any scrutiny. I found the crack after viewing a Reddish Motorsport video, I had looked before (with the entire subframe out) but I did not look in all of the right places so I don’t know if is new or was existing.

In my case the crack was located in the classic spot (i.e. left hand rear subframe mount at the floor crease). Why do our cars fail here? Don’t know but previously we could comfort ourselves that very few cars were affected but it seems to me that as time goes on (i.e. km’s) the instances increase exponentially. After stripping the vehicle underside and inspecting all of the subframe mounting points I found that there was only 1 crack and that it was fairly small (30mm long). Based on this I decided to weld the crack, fit reinforcing plates, inject BMW structural “foam” and repaint the underneath of the car.

Bearing in mind that the size of the crack (small) + the internal and external reinforcing being applied I chose to epoxy the reinforcement plates on rather than weld them. I had the necessary gear/skills to weld and it would have been cheaper but I felt it would have been too “invasive” when all things were taken into account. I also decided to use the structural foam in the LHR and RHF cavities as these are the 2 places where the cracking normally begins. This is because the LHR subframe mount is subjected to tensile stress (from motor induced rotational torque (anti-clockwise look at the rear of the car) and axle induced rotational torque (anti-clockwise looking at the right hand rear wheel). The RHF subframe mount is subjected to compression stress (i.e. the opposite of the LHR). The other 2 mounts (and ultimately the whole floor panel) really only seem to fail once these 2 stressed mounts have failed.

There are plenty of DIY’s out there so I haven’t gone into the full detail here, a few things to note though. Regarding the rear mount, since I had the subframe out I chose to blank off the rear cavity (using expanding foam) from the bottom of the car rather than inside the boot as per BMW’s T.I.S. Regarding the front mount, I spent a lot of time estimating the size of the cavity that the mounts are encased in and found that it is quite large. This prompted me to use expanding foam to keep the structural epoxy localised around the mounting point, this is not something I have seen done before. A lot of people use a hand actuated epoxy applicator gun but this is very hard work, instead I made up a mechanised unit as per the following photos.

Regarding costs the BMW structural foam was $263 per pack (2 x 420ml tube pairs) – I brought 2 packs. The reinforcement plate epoxy was $40/tube – I brought 4 but could have got away with 2.

If anyone is interested I have the gear I used for this job available (diff/axle carrier frame, reinforcement plate templates, reinforcement plate clamps and foam dispenser gun).

1. Crack viewed through the RHR sway bar mount (exhaust removed)

2. Close up of the crack

3. Home-made reinforcement plates (2.0mm)

4. Underside stripped and mounting points cleaned up

5. LHR mount ok apart from crack to the left (you need to look out for separated spot welds as well as cracks)

6. LHF ok

7. RHF ok (circular shape around thread is not a crack, it is the boundary line between the body panel and the threaded insert)

8. RHR ok

9. Crack ends drilled

10. Crack welded (gas - 2 passes)

11. Plates coated with epoxy after scouring with 60 grit and cleaning with electrical contact cleaner

12. Reinforcing plates fitted and compressed into place with 2D clamping plates (rear), not something I have seen done but a must I reckon

13. Front reinforcing and clamping plates (all left in position for 1 week)

14. Car fully masked in preparation for underside painting

15. Underside primed after degrease, scuffing and prepsol cleaning

16. LHR mount after base and clear coat

17. RHR mount after colour

18. LHF mount after colour

19. RHF mount after colour

20. Fuel tank back in

21. Rear axle on its way back in (note blue painted support tool which made the process quick and easy)

22. Expanding foam being applied between rear mounts as per the T.I.S

23. Expanding foam being applied to RHS of front mount cavity (through OEM drilling) – LH done too (although I didn’t fill the LHS with structural foam I prepared all sides in case I want to do at a future date)

24. Expanding foam being applied to the centre of front mount cavity (through new drilling)

25. Expanding foam being applied to the “tunnel” that runs between the front and rear cavities (modified version of T.I.S method)

26. Holes plugged (plugs at 11:00 and 4:00 o’clock in photo)

27. 4 x BMW structural foam packs plus homemade applicator gun

28. Applicator being used to fill RHF subframe mount cavity

29. Applicator being used to fill LHR subframe mount cavity

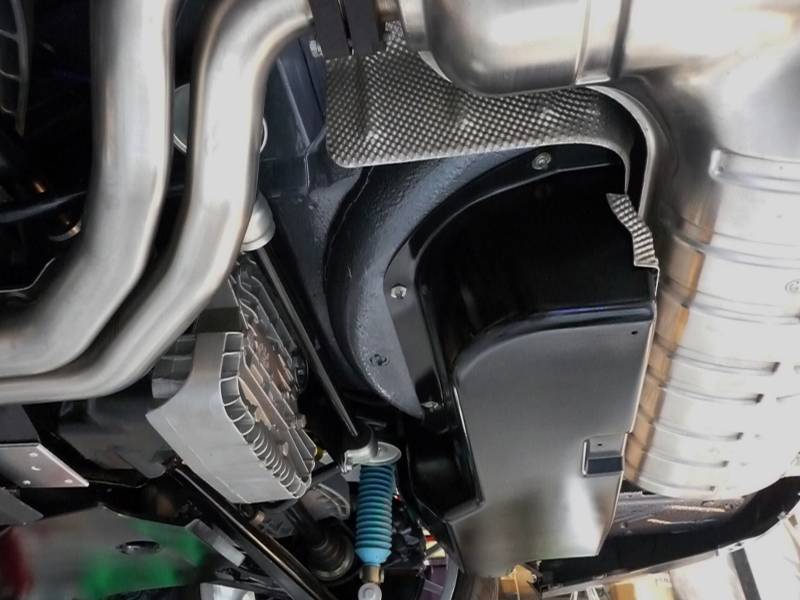

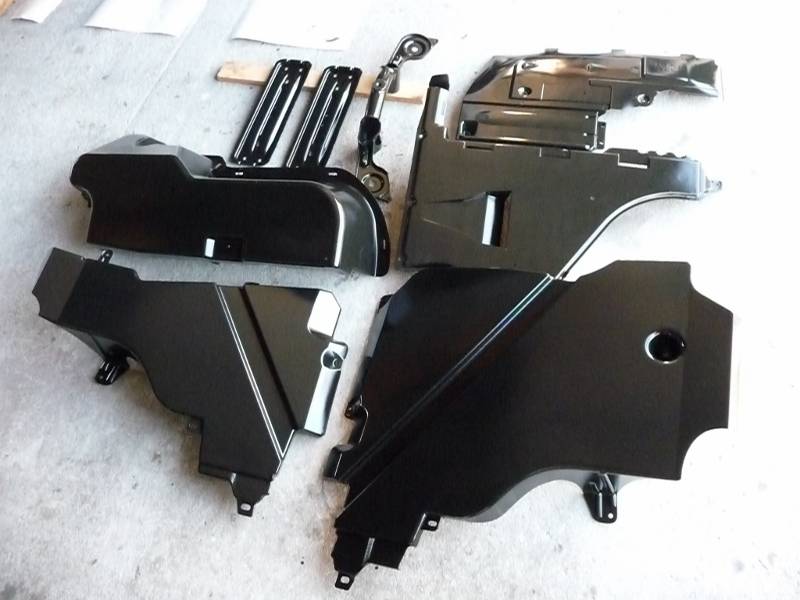

Last photos show exhaust re-polished and rear box – 3rd and final piece of work in the “gutting” exercise - last remaining fibreglass packing removed from the inlet section (patch at 2:00 the only evidence) plus underfloor plastics repainted

-

3

3

-

-

Be warned if you are using the 'lux flakes' method to revive your steering wheel stitching, it totally 'melts' away the paint on the center cowl. No problem I thought, I'll just rub it all off to be black - no, the black came off too

Really - as the originator of this method I am surprised - have treated mine 3-4 times without any problem - what mix did you use?

-

Most say you shouldn't mix passion and hobby with business as you will soon get tired of the hobby and lose the passion - Ray is a true exception to this rule.

Very rare to find true enthusiasts in the business who are out to look after other enthusiasts. I only wished he wasn't based so far away from where I am!!!

Ray is a long way from where I live (400K) not from where you live Tom (a stones throw), +1 for Ray though, he could have sold me a steering rack not so long ago but cautioned me to look elsewhere (my problem ended up being the strut top hat so another rack would have been a painfull mistake)

-

-

335 heading south out of Taupo - grey on grey rims - was this you Matt

-

Lol yeah, I think I'm screwed. I'll have some time (now) this weekend and will post details and advice for all.

It's a total f**kup but I like to remain positive. Perhaps this will be the reason to fix everything else...

Feelin for you - you will get there. I had a big problem after I did my top end check (soleniod pack soldered joint failure) which had me thinking I had totally cocked up the job. Great support from the forum (Tom) got me through - post your progress/observations - someone may be able to help you avoid the flat bed

-

1

1

-

-

Pretty riced out, but at least it has the go to match the show. Certainly fractionally less repulsive than all the auto 318s out there with ginormous wheels and aero additions that would add downforce at speeds that are only theoretical for the engine

Not at all my taste but I'm sure someone out there will love it!

Not at all my taste but I'm sure someone out there will love it!Well it is not me

-

-

Good luck with this - did the same on my S54 - internals look very clean - suggests it has been looked after

-

Same happened to me right after she let me buy it - no hiking for her. Got it repaired at The Tyre Cline (8 Fileshire Ave - 3850449). Great job but $120 per rim.

-

Very nice (but then I am biased)

-

1

1

-

-

I had convinced myself that my M3 ran better on 98, brought 3 x 20 litre fuel cans and filled up when ever I was out of town, turned out my soleniod pack was faulty, now (logically) can't see anything between 95 and 98

-

I have been following this and very much enjoying - well done - looking forward to your first drive (as you are too of course)

-

-

-

Thanks Paul, What oil did you use to Re Fill the Diff after you had changed the seals?

You mentioned in your thread about subframe cracks? Where would I look when under the car to see if there is any issues on my car in terms of this?

Not sure what oil was used - dealer did the job. Tom's your man for sub-frame cracking comment but it is the right hand rear mount area that is the problem - search M3forum for (endless) information on the subject. Can be easily inspected from under the car/in the boot - very rare problem

No dropping of diff needed that's for sure.

Just the bottom bolt from memory to allow the dummy shafts to swing down.

That's pretty useless if a dealership fitted the seals and pressed them too far ... the factory seal insert tools are basically idiot proof!! I can't see (if they have used one) how they could accidentally press them too far!! At least anyone competent enough working on it would have taken the measurement of how far it sat before pulling the old seal out (or checked the specs!!)

You are totally right Tom but to their (Jeff Gray - Palmerston) credit they drove 200km and picked up the car - trailered it to Palmy and fixed it. Especially impressive since I had removed the diff for them to do the work - I was wrapped with the service

E46 M3

in Showroom

Posted · Report reply

Very nice - congradulations