-

Content Count

90 -

Joined

-

Last visited

-

Days Won

14

Content Type

Profiles

Forums

Gallery

Calendar

Store

Everything posted by gaijin

-

It does, but beats external pumps making a racket. Just made sure no chance of shorts etc

-

What a bloody rigmarole, couldn't sleep so spent 4 hrs finishing the tank off, ready to reinstall. Ended up putting the third pump back in, meh. Perhaps drilling a hole into the top of the filter regulator WASNT the return, idiot, it was the second fuel feed to the front, so instead of plugging the hole, I may as well use it. Would be hard to do this whole job in the car and with any fuel at all in the tank, you'd be passed out, as I did when I tried it last. Lots to build with two hands in the tank. 100% happy with it all now, what can be replaced has been replaced and enough fuel for whatever eventuates.

-

In between watching the Nurburgring 24hr and finishing the fuel tank off and finally getting the Golf R back from E&H, its been busy. Golf managed a bit less than 370whp at all fours, feels enough for the daily. Runs at 28lbs, had a boost tap sitting under a map sensor causing heat soak into the sensor which I sorted/removed afterwards, so the dyno was run with 45+ deg C IATs, so expect a little higher hp now that I se low 20's deg C on the mway. Meth/water injection half installed, almost the last job on the project. Bits turned up for the fuel tank, found some factory limitations with the filter/regulator assembly. The fuel feed into the filter then regulator is tiny. Opened up the old one to investigate, very unserviceable. Perhaps later Ill replace it entirely (for an aftermarket performance type one, much larger lines etc) if I need to. For now its a OEM replacement. Yip, this is the internal fuel tank feed line to the HPFP (and also port injection rail) , doesn't matter how many pumps you add (apart from the fuel pump controller getting pushed past its capacity), this will be the limitation. Added some foam packers that sit against the tank and the chassis that over time disappeared. Redrilled the new fuel return into the top of the filter/reg. Moved the position slightly as it was rubbing against the fuel supply and return connectors. New O-Rings for the buckets etc Then had my usual garage party Friday night session to have a look at the engine bay bits, Painted some stuff, made some sh*t, fixed down the radiator reservoir with mounts

-

Haven't done as much as planned but progress nonetheless, So all intake ports cleaned up and the mess is gone, likewise nice to work around a clean block and bay. Put the intake manifold studs back in after a clean up, left the furthest back one out, to replace with a bolt, as it is the one that makes it more difficult to take the manifold out/in. Removed some aircon lines as one doesn't look too happy, for replacement/fix later. Next larger things to make fit are the radiator and PS reservoirs. Had a few basic brackets that I trying to mock fit for now, to then test all the other clearances, hose connections, inner wheel guard etc. Still the stock 135i rad res. no the 335d one often used. See if a reorientated throttle body gives it more space, unlikely. Ill get the port injectors in for a test this week and make sure they are good, spray pattern and flow etc.

-

Totally on my mind, after watching the P1 and Tavarish last night C02 blasting , yeah drool....makes my project look like project cars for dummies... Here is me selling my walnut blasting machine and a 30kg sack of walnut 2 years ago...sheesh Carbon gunk removed, mostly onto me, at least well transferred...

-

Cool projects still have shite jobs Not too caked up but port inj means it'll end up in the cylinders, so needs to be cleaned. Used brake cleaner and a HD pipe cleaner, prob about 4 passes each, then compressed air and more brake clean. Came up decent. Cleaned up the gasket surface Also gave the block some love, diluted HCL acid sprayed on, left for 15mins, then rinsed off. Had a fair amount of oxidation, like a powder built up in places. All cleaned up. Gave the cut engine cover a paint job in tungsten mett. Removed all the engine bay loom, which was taken from the donor 335i auto. Manual and auto looms are a little different. That's this weekends job, make a decent loom from each, fixing the bits that er need fixing.

-

Some relief from the rain means time in the garage, hope you lot are not getting flooded! The intake manifold hit the alternator, so got hold of a phenolic spacer, 26mm thick with cut outs for the o-ring seals on one side. Took the grinder to the alternator also to bring some of the fins of the back of it. Clears it all by maybe 2-3mm, so that's ok now. Seller offered some cash back for the non-fitting manifold so I'll leave it at that. Can slowly put the cold side back together. port injector carry 750cc @ 40psi injectors, plenty for now. Hot side gets a short filter, about 90mm long. fits well. Changing to a banjo top oil feed adapter to the turbo, as the previous version stuck up above the turbo, meaning the bonnet would likely hit that first, good fire starting opportunity. Starting to feel like its coming together

-

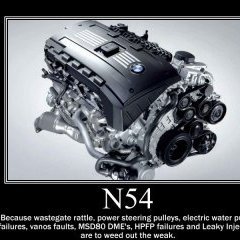

Got the fuel tank removed, needed driveshaft to be removed, handbrake cables released from inside car etc. Wanted to review previous work and make sure Im 100% happy with it. The stage 4 Precision setup has 3 x walbro 450 90000267 pumps- e85 ok. The third pumps sits off the side of the bucket and was needing to be installed to the bucket inside the fuel tank which was fiddly. 2 x 450l/hr is sufficient for up to 1k hp so will just install the two pumps to keep it clean for now. Much happier with the completed bucket. I cleaned out the tank inside and out. Some minor junk was left in the tank. Little cable nick fixed # Note the O ring coming out, replaced O rings. Position of return feed really close to the tank outlet, will redrill with really limited space when the new reg/filter arrives. Also a part broken female receiving clip. New part fixes all that. Noted the crimp connectors are pretty crap so soldered all connections, fixed a minor nick in one of the wires to a pump. Ive bought a new regulator/filter (the LHS tank hole) to put in. I note that this will be the next fuel system restriction, may look at mods considering Ill run a regulator in the engine bay and pulse damper likewise a separate fuel filter that's already installed under the car. Next job is getting it all back in, then going through the fuel line setup under the car so it meets cert requirements in regards to how they are fixed to the chassis. My old front facing manifold The front facing intake manifold arrived, yet doesnt fit, it interferes with the alternator at the throttle body weld interface. BEWARE buying this off Trade me. It'll need a spacer of sorts at the head to space it out circa 30mm. My N54 and engine is not unique in any way in this regard. Unsure if Ill return it, fix it or what. My last one fit ok. Bar going for a DOC or Plazmaman at huge expense, which is out of my budget. A spacer kind of partly defeats the purpose adding another air/boost leak potential. Project life huh

-

Sheesh, despite plenty of garage time over the last 3 days, doesn't 'look' like much has progressed. oil pressure regulator v2 arrived and mounted forward of the turbo on a piece of 5mm ally. Hoses will need redoing. No independant drain is good. Turbosmart says 100mm away from significant heat sources. Tried a few mount locations, almost decided against the engine block (which would've been a nice tidy out of the way place, but then again a recommended oil pressure gauge and a washable filter means a local reachable position is preferred, so that decided the location. That took an age, I wish Khabib could have 'send me location' would have saved time.... Also pulled the wastegate apart to turn the port positions, turbosmart seem to be ok with three bolt configs which means an odd range of options for wastegate top/bottom pressure port positions. i.e. annoying Mounted the stock water outlet from block to waterpump, fits snug to wastegate exhaust pipe. Bought a bunch of heat reflector sheets, hose sleeves etc. Started the boost solenoid mac valve install, not sure where to place it yet. Also decided to start a 3.5" turbo dump over the 3" since I think it'll fit, now that I have more clarity about fitment of everything down there, I did go though through the wiring parts and noticed the changes in the N54 scene since I started/ better said since I stopped driving the car for the ST conversion the build, in regards to port injection controllers. Usually a JB4 and additional injector controller etc etc was to the go to, now its the motiv reflx plus. start saving.....yet it does much more than just the PI part. Photos just thrown in no specific order Should get hold of the new front facing manifold tomorrow or so to get the cold side work going, should be miles easier than the hot side. Did buy some new brake decals and paint to freshen the calipers up at some point

-

Some minor but important changes I couldnt get the ex manifold out of the car without lifting the engine on the RHS, a complete pain. Solution was to pack up the RHS engine mount with a spacer allowing ex manifold to go in and out as it should This allows enough room now without having to resort to beating the chassis strut area in as many people do, clearance shown in photo 7 I've removed the waterpump entirely to check all hose fitments. Reason for that is the inlet hose to the waterpump was just rubbing on the oil return to the block AN fitting JUST, enough to wear through in time. Ordered a modified factory return that sits up and around the pump still with an AN fitting, welded to the end. Everything looking good and attached apart from the change in direction with the oil pressure regulator for the turbo. The mk1 Turbosmart OPR requires a plumbing back in of the oil return that is not in the same return line as the main turbo oil return drain, which would mean either a whole separate line to the sump or using their new mk2 returnless version which I've bought from North Short Toyota and the great team there. Ill get the final oil lines made up once the OPR arrives which should at that point complete the turbo plumbing, bar the heat shielding sleeves and the mounting of the OPR. Yeah, that and the boost lines for mac valve solenoid etc. This is about as close to a final turbo plumbing solution as its ever got. Once Ive finished all the lines Ill keep going to finish the downpipe and look to feed the wastegate dump back into the main dump to keep LVVTA happy. Crap bimmerlife coil harness solution. Ill see if I can rescue it first.

-

Thanks Elias, looks really clean and plenty of space too. Looks great! Ill see how I go, may I ask about how much $?

-

Audi R8 coil packs install They do not fit immediately, require some minor mods to fit tight on the new plugs remove stainless outer sheath, pry apart, pull off. Keep inner SS sheath, cut back rubber grommet to help lower the coil onto the plug. Reason is that the coil doesn't sit low enough over the top of the plug Had a look at some yubtub vids but often they dont show that removal of the outer SS sheath is the key for the coil to sit lower to connect to the plugs. The bimmerlife R8 coil harness is garbage, looking at alternatives for this

-

Change out stock plugs from wrecked 335i wagon, to um Stage 2/3, cant remember Pulled all the valve cover wiring loom out of the way for now, will worry about tarting up the engine bay later, with new cam cover, pcv, heat shields etc BMS/ Burger thermostat and AN fittings in for oil coolers run in series Who says there just a few lines coming in/out of the turbo Time to check fitment inclusive of turbosmart oil pressure regulator, likewise water feed ally pipe. Itll need to be changed/modified.

-

Back to the 1M faker, LHS headlight lens being readied to seal back up As almost as large as you can fit in dual oil coolers installed. RHS mounts as per the stock one, LHS requires a few parts that were not originally on the car, shown below, This allows two of the three mount to attach to the chassis rail, this part get placed between the chassis rails and the front crash bar as per the RHS. Its on its way. Seem to fit ok, holes in metal duct were for brake vents from the original owner. Rear interior/boot reassembled, left out any part that isnt particularly functional. Meth tank cleaned out, lines routed. Nex job later today is removal of fuel tank, to both clean out any residual crap and rinse remainder of fuel out. Also to ensure the stage 4 triple intank pumps are secure and finalised, including fuel lines and relays, hobb switch, ground wires, supply and return lines etc. I never truly finished this job to a point where Im confident its done properly. Probably fine, just dont want this to burn the car down by being lazy. One part Ive been scratching head my head on literally is the half cage. It dawned on me that I quite possibly bought a LHD type cheap locally. The diagonal bar would preferably go the other direction giving me the space needed to no knock me out, or add so much padding that my face is up in the windscreen. May remove entirely. Leave this for later. Found a genuine BMW motorsport gershifter new. Lest we forget 🥀

-

I wish, it's an 01 S but with 20kg removed from a lightweighting programme, inc gearing upgrades, single injector mod etc. Amazing to see how easy it is to remove weight from replacing the rear disc, horns, radiator fan, axles etc etc

-

Thanks Team, Now that FINALLY covid, work, kids and the 550hp mk7 Golf R is finally off my hands (in terms of spending my spare time working on it) and more or less done (pending TVS tuning by E&H Motors for the large turbo as we speak), its time to make room for solely working on the 1M clone. Golf work included adding a second large intercooler, both stock position and front mount, certification work, seat belt anchor plates, new BBS wheels, new semi slicks, methanol injection etc etc. I had a forward facing intake manifold on the 1M, but some %^&* stole that from the car a while back, so a replacement has been ordered, likewise new sump gasket and bolts, while im under the car. Will take mains and rod caps off to check bearing wear while Im there and possibly replace with ACL race bearings if the're average enough. The rollcage was on T.me a while back and I couldn't but haggle and take it off his hands. Its motorsport authority certed. Ill take some snaps of the racetech seats install that's done and the rear interior striped out over the next few days. The cage is tight fitting, mostly with clearance to my head with the type of seats and seat positioning, will need some tweaks or a different type of drivers seat, In the mean time I've partially finished the headlight lens replacement alongside angel eye install. I reckon Ill be dusting that welder off this weekend and hooking back into this beast finally. That and trying to get used to how 195hp and 175kg feels like below, with carbon wheels and a full race only Ti exhaust and tune it just wants to; a) - make you deaf b) - wheelie EVERYWHERE

-

For sure, that kit is pricey, looks great but I'm too far in to go back now ...kind of rather make my own for the sake of it

-

After a lengthy lay-off I can say Im back and ready to keep building. Reasons for lay-off; 1. Let 3rd child grow up a bit more (kids come first) 2. Built another car in the mean time (its a VW dont hate ok) 3. VW virtually finished (its the daily so it was prioritised over the rest of them) - Now FBO inc. larger 550hp turbo, big fuel system, Tein Monosports, swaybars, brakes all round etc etc 4. Lots of drone fishing, A coulpe Golf pix but then onto 1M Clone... So 1M Clone? Where did I get to? Single turbo thoughts, strip interior mostly out, half cage installed (MANZ approved), had a ST ex manifold made up, extra high heat ceramic coating via HPC to , turbine housing, CHRA and a silver coating to comp husing. Needed to make up downpipe, wastegate needs to be plumbed into DP, oil & water lines need some work. I have an inverting TIG at home, which now sits proudly in the dining room as the welding station. Keep back kids. Ive made it out of 1.8mm thick 3" SS304 using 1.6mm rod and tack welded for now which will tap into the 2.5" twin exhaust. Now its longside the engine mount I can prob either keep going in 3" or widen to 3.5" then a merge into the dual 2.5". Sundays are usually the day for car work these days Now that Ive worked out syncing from Google drive to the PC and phone life is easier to post, apologies for the delay Crucial learnings about project cars, dont let layoffs defeat you, put a cover over it and be patient, the time will come again when the time is right

-

So managed a few hours on Sunday. Yay. I bought a turbosmart oil pressure regulator. Why? With ball barian (as my son says) shaft supported turbos of late, there is much increased need for oil pressure control. Please google why so you don't blame me. Installed it. It requires an oil return from excess oil pressure bled off from the supply into the turbo oil drain, adding a further hose or three. Since I haven't added any further cooling capacity apart from the change in the BMS oil thermostat which Im in two minds about (operating range far too wide, from 70degC to 120degC), I'm working on a much bigger oil cooler in its factory position perhaps running a better aftermarket thermostat. This requires much bumper off bumper on action to make sure the cooler is mounted in the correct position for the 1M air feed. I've bought the parts to run another cooler on the pax side albeit a touch smaller. Start with a new replacement drivers side and see if she's works better. So says engineering, that hp and heat output are closely related, which only goes south toward heat as you throw more fuel n boost in. So says engineering... Time to strip the old wiring add ons to the existing loom and add to the fresher loom. if all else fails RTFI. read the fuggin instructions. So bought and put together the BMS short shift kit over the BMW performance version. I chaged out all the bushiongs at the gbox end for delrin (aka hard as f*ck plastic) and the rear with a stock BMW but new. Ready to go in. So looking at the PS and radiator tanks, there is plenty of room to the East, so a few lines made up and she's there. Otherwise we are getting there slowly.

- 104 replies

-

- 10

-

-

Whoa! Don't get me into this Nick......sheesh!

-

"Need some turbo hoses bro" GSS = Greenlane Speed shop = 09 525 6858 I think I asked for 200 series Black stainless braided teflon hose with black fittings Good for maybe 150+ degC apparently, ok for oil etc. Not seen yet is the turbo oil pressure regulator. This will make the feature this weekend and some bullsh*t reason why...

-

Right, spent half the day on getting the drivetrain and subframe bolted up. Damn hot today, even the tools were cooking in the sun. Stripped out the old loom and used the one provided by the new donor engine. Need to de-loom the JB4 and assorted 2step and stuff and bring this to the fresher loom. Manifold fits well, its tight-ish in many places. Likewise the wastegate seems really tight. Look like I'll remove a few sundry brackets from the area to get more clearance. Further chopped away at the engine cover to fit both around turbine & comp. housing. Installed the BMS water supply in/out in 6AN I think, and oil supply in 4AN and drain fittings ordered in 10AN. Blocked off one water supply & return. Big air filter fits well, about 10mm clearance around it to the underside of the hood. Bought me a BMS shirt shift kit and some other billet linkage kit. Ill detail that next time. I can get the oil & water lines ordered this week, likewise drain line. Re-fit both front struts and torque check every bolt/nut. Working out how the exhaust turbo back down pipe likewise how/where the wastegate dump will work should be a challenge. Bring it on... Just need to relocate the radiator reservoir tank and PS tank and we almost there. Here is the ECU fix I undertook capably as a cripple. Issue was noted when a super sweet 2 step backfire in the waterview tunnel then made the car a little odd, some minor fuel fluctuations. JB4 read that there was no signal from bank 1 O2 sensor. Yet the replaced sensor also didn't work. Guessing not the sensor. Opened up the ECU and changed the MOSFET that read as open circuit, which, 'blow me down with a barge pole' powered bank 1 O2 sensor. Sweet fix man! I ended up changing all the other MOSFETS while I was there. Cost about $4 each. I used automotive grade ones, for high temps etc. Slightly higher in spec than the factory ones which are notorious for being sh*t in the stock DME/ECU. I removed also the clutch delay valve which peeps say is a good investment. Basically its a bored out factory one with a larger internal bore diameter.

-

Damn knees. Who thought they were important FFS. Some leave days are booked this month to get the guts back in the body and pumping promise.

-

Meh, quick test fit with subframe out. Its a snug fit without being tight anywhere. Probably 15mm the closest to anything, so decent heat dissipation. I'm not expecting much lag. I'm planning to push the refreshed stock block and see where we get to. I'm thinking around abouts like this one, which has the same sized hairdrier; The turbo size aint too far different from my little 2 litre 4 banger in my Mk 1 Celica...