-

Content Count

90 -

Joined

-

Last visited

-

Days Won

14

Content Type

Profiles

Forums

Gallery

Calendar

Store

Everything posted by gaijin

-

After a minor mishap with the long block, I have bought a wrecked 335i wagon with low kms, swapped the long block over. Also sold the rest of the 335i to Brent @ BMWorld. Good b'stard took the engine out for me too. Did the rest in the driveway. Managed to tear my MCL in the right knee getting the engine off the trailer and onto the crane. This stopped car play for 3+ months. No pain no gain huh. Strong but not strong enough = groan. But the engine is super clean, zero oil leaks from anywhere. Swapped all my bits over to the fresh long block. Whats to blame for the engine re-fresh? New injector locating tab falling into chamber causing a bent valve and hence no compression. Stink bro! According to many a friend they would have given up here. Shown here is a stock one and they munted culprit. Engine didn't even do many cycles before damage occurred. Sold the RB Turbos to Mike to turn his 335i into a drag car. Stage 2 pump gone, 3" downpipes to a Natalie down Chch way. I've changed the clutch to a Spec Stage 3+, solid centre single plate. See how it runs without springs/damper. Might be ok. Add M Factory light flywheel too. No longer a dual mass thing. Factory DMFW is a really heavy thing. Its taken since July 2017 to get this manifold made up, fitted correctly, flanges CNC'd and test fitted in Australia with the Garrett GTW 66mm (6664 in Precision speak). Hell of a Xmas present though. Whether this be the manifold or possibly the best successful test of my patience. I'll be taking the ex housing and manifold to HPC to get their extreme coating applied this week before it gets final fitment into the bay. Pardon the delay, but I will soldier on. Should have the manifold bolted up next week once its back from HPC. A few lines to get made up, bought and in stalled the block blanking plugs for the dual oil and water feeds to the stock twin turbos. Now to be single feed to this beast. Stock TD03 standing adjacent. Biggest difference is the turbine diameter, sheesh! Also managed to fault find some blown MOSFETS in the DME/ECU and swap them out to tougher versions. Engine was misfiring at times, thought it was the 2step munting the O2 sensors, but ended up being ECU related. Can share fix details if anyone interested. Its a cheap and easy fix, with a soldering iron and a steady hand.....

-

Yeah I installed my own I/C's, on five of my current cars, Vag/Vag/BMW/Toyota/Nissan. If you have the skills money and time, sure do it. If you want to supply OEM parts to a mechanic who says no, then walk away. They are effectively doing the same thing. Bring them poor quality non OEM 'performance parts' then they have very much full right to say go away. I've tried to install poor quality junk, I tell you, what a waste of my time! Would hate to think that Id charge customers to install junk that doesn't work or is a butcher job. I see both sides here. Now truly getting back on thread, good to hear Nathans VRSF 7" is installed! Probably need that stage 2 in tank pump soon right.....likewise the meth spray....

-

Managed a little bit over the weekend on wiring up of the JB4 additional injector controller, getting the pumps into the tank and wired up, all hoses connected etc. Almost there. Managed to get the mirror attached to the base plate for the RHS. Ill mount it up and see how if looks, then make adjustments from there, ready for scanning. Its pretty solid/strong so far, perfect for playing around with, using marine ply then thermoset plastic, let it set then drill into it for the mounts. Then I can play around with the mirror angle. Bog & beatification comes later...

-

"Climate Change" = one weekend we're underwater, the next I'm frozen. Meh whats pneumonia got on BMW progress.... While it rained Friday night, I played with some polymorph thermoplastic as a material to set some mirror bases. Meh, ended up making a HUR of a handle for a filleting knife for bigger Gt Barrier catches instead. Ended up using some marine ply, working the mirror base contour and then belt sanding the rough contour of the mirror. Its a start. Sat & Sun was progressing with engine bay fuel fittings, finishing off wiring loom and mounting the fuel pressure regulator for the new port injection. I hung this off one of the manifold studs, the same one that stabbed my hand pushing on a new fuel line fitting to a cold hose, at least blood helped slide it on. B'stard! Used the same wire protectors to cover wires extended for throttle body and pre manifold MAP sensor. The rest fit ok. Lost half a kg trimming the engine cover to fit the injectors. Likewise closing off the replacement of all beefy fuel lines and fuel return upgrades. The first pic shows zip ties all over the place. The RHS shows one dash6 fuel return from the low pressure port injection rail to the tank, one dash6 450GPH fuel pump supply feeding through a fuel filter, and one dash6 line feeding into a 2-1 junction. The LHS side shows the same fuel return, with a dash8 main fuel feed line to both the high pressure pump and port injection rail. Uses aeroquip push lock fittings, some used from another project. Modified the stock fuel line brackets to make room for these. Yip, I'll trim the zip ties and rotate the ugly bits. The fuel tanks RHS bucket needed a fitting drilled through to feed the third pumps outlet, seen carefully as the vertical black line fitting at the top. The main line feed is horizontal from the white plastic, both unattached. The tripe pump setup is now installed in the tank, just needs the hat installed to the bucket. I get limited work time before I get a bit dizzy sniffing fumes, hence slow progress here. Two large hand working a small hole, damn....Black random wire heads to the new intake manifold hobbs switch that closes at 15psi, to trigger the relay and fat fuse to power the other two pumps for the port injection to get ready for action. re As for these mirrors, damn. The glass itself is so convex that you could mount the mirrors in a wide range of positions and still see back. But the key thing is here, visually, how do we want hem to look? Check some mean pics of hot DTM machines. I see some upward angle ala hornet wings style, alongside some possible inward angle...nothing a belt sander cant deal with right? The ex. manifold and steering column shat are almost done. Gotta beat this delivery and get the new setup ready for round 2....

-

Nathan, as a modification, what difference to you hear/feel with the CP, BOV and filters swapped out running the auto trans?

-

Sold the VRSF charge pipe and HKS BOV and BMS air filters to an other guy here Nathan and installed them on his car today. Slowed progress today, but good to share spare bits to others. He seemed happy with the results and new found noise. Car sounded good for sure. Managed to finish off the engine bay fuel rail plumbing, some new push lock fittings, fuel regulator needs to be mounted. Installed a new return line back to the tank, they don't have one factory, using aeroquip -6 lines. Throttle body wiring extended, likewise 4 bar MAP sensor wiring to new charge-pipe. Ill head down Jaycar this week and grab some wire tidys, make em look stock. Took a 1.75" to 2" 90deg elbow from front turbo to relocate the air filter on the drivers side. Bought a couple K&N filters to run as temporary since the others are sold. Piped up the intercooler pipework. Excuse the ASBO blue hoses, they'll go once the ST goes in. So the I/C is in, but needs to drop down about 30mm so the bumper can go back on. Saves me hacking that up. Had my helper yanking on some hoses Still need to mount the new giant (for a little bimmer) dash 10 fuel lines under the car. They are in position. Three fuel pumps are installed in the tank but need finishing. A real arse of a job. I gave up last Sunday on this part of the job after getting real dizzy sitting in the car with hands in the fuel tank for a few hours trying to get the wires attached, all so bloody fiddly. Needed a lye down... Fuel return line needs tapping into the fuel top hat. Injector loom installed, just need to wire in the JB4 port injection controller. I had a Split Second additional injector controller, but the JB4 version has heaps more fail safety devices so will run that through the main JB4. Then we almost ready to test the port injection and E85! This will be the last hoorah with the RB turbos. Lets see what we can get out of them.

-

mirror time. Baby approves. chopped up the old stock E82 ready for 3D scanning Motorsport mirrors, both weighed 147grams each. Stock mirror is 1200g each. Left glass fits nicely, right side is very motorsport, needs some glass sanded back to fit nicely. Damn rain, stopping play outside.

-

Good progress Friday but shite Saturday. Managed to wing a weekend off from the Fam Dams so I can play with the car. After convincing myself that I should definitely NOT to upgrade most of the fuel system in one go, I woke and did just that. SO removed the Stage 2 fuel kit/pump a Walbro 450G/hr, I put together a Stage 4 system of 3 x Walbro 450G/hr and meaty electrical system. Almost there. BEFORE = Stage 2 - 1 x 450G/hr AFTER = Stage 4 - 3 x 450G/hr With the intake manifold change, there are some wires to extend, my friend Lars will do this tomorrow or else he can stop drinking my beers. Dummy slapped the turbo into position Hmm, heaps of sh*t to sort out

-

Yesterdays guess would be 410rwkw, = 530 whp = circa 600+ hp. At the current turbos limits. Today zero hp as the car is in bits. All the fuelling kit and turbos bits arrived. Removed VRSF 7" thick IC. Compared to the new joined core IC mothership, its mighty heavy. Purists look away, the butcher was in operation today getting this sucker in! Also the 2JZ ricer style intake manifold and port injection went in. This fit well actually pretty surprised. I'm attempting to get the new IC completed, with the intake manifold, while keeping the RB's and inlets in for now. Then set up the port injection and fuel kit and E85, then finally strap the GTW37 on. Car should be back running tomorrow. BEFORE AFTER

-

Scott at Fraser Cars finally placed the certificate by LVVTA defined as 'heavily modified/scratch built car' on Monday. Only taken about 4 months. Ended up doing a bump steer test, but no drama's there. Plate ran out of space so the additional info is on the paperwork. No room in the engine bay so its loudly placed on drivers B pillar. The two step installed is eating pre cat oxygen sensors. Not really surprised. May look to remove this function. There is little need for 2 step from standstill for a daily, but its sure fun in the new Waterview tunnel. Ala sort of this vid below apart from louder. But at speed its quicker to get the shotgun/flame boom part. Especially with hardly much mufflering in the exhaust. New progress with some non performance items, managed by some grace of the BMW God to find & buy these, OEM DTM E92 M3 GTR mirrors direct from BMW Motorsport in Germany (the CF housings and mirror glass). They are not bolt on's to an E82, but I have 3D printing in ABS at the ready and my old stock 135i mirrors to scan and model from. This will form the part that joins the CF mirror housing to the door, the triangle piece. They are circa 2012 items. IND makes them for a E92 but wants spastic money. Rather do it Kiwi and make me own ala the first photo from RKP composites. These arrive in a fortnight from .de Daniel from Brisbane has updated his RHD ST exhaust manifold. I'm not 100% on the design of this (due to heavy space restrictions), but I really like the CNC'd flange for sure. Also he can provide a slim Jim version of the stock steering column shaft that is so chunky and limits downpipe size likewise wastegate pipe screamer/plumb in room. Noting that the stocker is fat for a reason, by providing a crumple zone at its lower part in the event of a crash. Saves the legs n all.....I'm still keen to get hold of this over a local custom fab'd one which should save R&D time and both are being fabricated by Daniel for the NZ clone. In the mean time I wait patiently as usual this time for a new O2 sensor to turn up so the car wont splutter around at 7lb boost. Should be in this weekend and back to full skidz strength.

-

The clone is usually at Caffeine and Classics each last Sunday of the month at Smales Farm North Shore, come have a look! https://www.facebook.com/CaffeineAndClassics

-

threw in a revised oil cooler valve to increase oil flow to the stock oil cooler, along with new covers

-

Yeah a fair amount of bits to sell, someone has there hand up for CP/BOV/7" Intercooler already

-

Something to do while it rains, install a titanium wheel stud kit. Fronts have some decent thread clearance, i.e. could have made them 5mm shorter, but rears are bang on. Look preeeety Before After and better news, the turbo/intake manifold/intercooler is in the country, likewise stage 4 fuel system finally on its way from Oregon thanks to YouShop. Bought pretty much all the other parts from ST conversion, coolant and oil fittings, short nose air filter, boost solenoid from BMS. Specs on turbo is 67mm - 65mm turbo using a newer GTX3584R comp. wheel, dual ceramic BB Garrett core. Unsure on ex. AR ratio as yet. Made 570hp @ wheels on a lowly 17lb on the N54. Ill be pushing much higher than that. Android already loaded with E85 ST map, its keener than I am!

-

Had a catch up Dan this avo after leaving work early, he's happy to receive the car this time next month to fab the manifold and exhaust. Better start collecting all the other bits.... Photo of Phils 335i from Melbourne, who is packing the parts as we speak.

-

Just bought this. http://www.e90post.com/forums/showthread.php?t=1391643 sh*t just got exciting! Ill push the clone over to Dan Slater @ Slater Fabrication for the manifold, he does great work, when you can ever book some time in... Thread from where the kit has come from; http://www.e90post.com/forums/showthread.php?t=1291848

-

After a twice round Nth Island in a month with the car, it performed perfectly. Amazingly. Great to get on the open roads and mix it up with the locals and other fast Euro cars, new RS6's, new M4s and give them a taste of the 1M. While moving away from E85 stations, I tried octane boosters in the fuel tank. While it worked for the engine, it was bad on my health, the stench and irritation with fumes coming back into the car with windows down was surprisingly bad. Anyways, car cleaned, LED lights installed into the cabin, external LEDs installed and coded and Blackline tail lights installed. The rear 275's wear showing minimal tread depth, time to try something a more chunky. Enter 295/30/19 Conti Sport Contacts. 2.3% less circumference, meaning it'll be like changing the diff ratio from the 3.15 it is now to a 3.22. The tire fits, but its getting tight. Could potentially do a 305. Its on a 10" wide rear rim, so fits the rim better than the 275 did for sure. The extra width should help with grip. Still waiting impatiently for some other parts to turn up for the fuelling upgrades, but not a show stopper for now.

-

Talking of porkers, perhaps the 1M needs to go more J Lo?> Some steel over-fenders that I had made up recently, fronts also. RIP Kirsty Webb, thanks for the memories and mud on the car xxoo

-

My estimate is around standard minus a few tens of kgs, say 1475 kg. A bit of a porker still. Apart from getting rid of 'bits' that are not deemed necessary, carbon boot and the mods done, some of which may add a little weight, some further work is to come, Have some further weight reducers approaching, titanium wheel stud & nut conversion (2 weeks time) and a lithium battery, should drop about 25kg https://ozmoengineering.com/product/bmw-m12x1-5-studlugnut-kit/ Battery brand tba Maybe seats in the future, but havent found something streetable that fits me, 6"3 and 105kg. A bit of a porker still.

-

http://www.datazap.me/u/gaijin909/log-1493954460?log=0&data=1-4-18 Showing a 3-4 pull, AFR's around 13 to low 12's datazap.pdf

-

where can i source a manual conversion overseas?

gaijin replied to jeremy's topic in General Discussion

try ebay.de then use translate if its hard to source locally -

I've added a part build thread on the projects forums, will add to that thread as updates come through

-

The first photo is the rear turbo outlet pipe. In RHD this pipe has to clear the engine and steering shaft. THey crush the tube in 3 sections all around the same place, terrible flow reduction. I ground the sections out and plated in SS then ground smooth. So this pipe flows hot pre-intercooled compressed air. I then wrapped it in heat shield wrapping stuff.

-

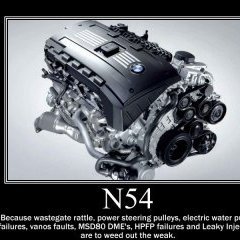

I havent really put much up about this car to date, probably start something here. Build List 2008 135i N54 6spd manual Jap import Standard N54 3.0 6 cyl twin TD03 turbo engine and 6spd manual, replaced upgraded BMW 550i pressure & clutch plate, stock dualmass flywheel, hard gbox mounts and braces. E92 m3 rear end swapped, subframe, LSD, all suspension arms & links, hubs, m3 front arms/uprights/hubs etc. Hard bushes installed for subframe and a few rear arms. 1m genuine panels all round, replaced via factory BMW repair methodologies AP Radi-cal brake kit all round, 6 piston front 380mm, 4 piston rear 390mm, SS braided lines. Full floating rotors on aluminium hats. KW v3 coilovers, bump & rebound set up, front vorshlag top camber/castor plates set up 2deg neg camber. H&R sways front/rear, adjustable end links set up for lowering 245/35/19, 275/30/19 Hankooks to shred for now. 295/30/19's Continental's ordered for rear, 245/35/19 Michelin PSS Cup 2's for front arriving mid June '17. Rob Beck Next Gen turbos, Billet 15T Compressor wheel/RB Bullet nut, TD04 Thrust upgrade, High flow TD04L 11-blade high aero turbine wheel/RB high heat shield, and RB high flow oil drains. Custom turbo outlet pipe, modified SS section. See photo 1. RB silicon turbo intakes, stock filter placements, big filters from Burger Motorsport VRSF 7" thick Intercooler, RB turbo inlet with HKS SSQV blow off valve. Ordered "Colossus" Intercooler to replace 7" VRSF. Now running full methanol integration via JB4 ISO with CM10 nozzle, 60% meth/40% H20. Running 65 additive on JB4, adding meth at 6lb/in2, or 0.4bar onwards once oil is at 70deg C or higher. Cant stress how good the meth kit works, Any flow restrictions, knock detected or avg ign retard the boost gets brought back by the JB4. Previous to the meth kit going in, the IAT, intake air temps, got really high, in traffic would see close to 50deg C. Took a long time on the M'way to get it back down to mid 30's, which would see the ECU pull timing and boost aggression in the mid range. Now with the meth, each time you floor it, you can watch the IATs drop pretty quick, much better repeatability of power. Means you can spin the wheels over 120. Ive tested the car up to 27lb/in2, 1.9Bar boost, but have settled to 25lb/in2 circa 1.7bar. With this it'll slowly pull in front of new GSXR750's from standstill and easily from 180+ on closed roads. I put into the main fuel tank a blend of about 60% mobil 98RON and 40% E85 from the Gull Forest Hill. I get 300kms from the tank as a daily driver. The JB4 ISO is set up as a piggy back to the factory ECU to control methanol and boost and the full data logging which provides a live bluetooth connection, so the phone is a mini dash too. The ECU is reflashed via MHD tuning (free to DL, then pay for each map). I run the hybrid turbo E85 map or the race flash depending on the percentage of E85 is in the tank. Im limited currently on two fronts in regards to the power output of the car. The turbos are at the limit of airflow efficiency, and secondly the High pressure fuel pump and injector flow capacity. The meth spray is adding fuel which Im using to maintain AF ratios. This used to be considered 'unsafe' as there were little/no warning or safety devices that would protect the engine if there was a failure in the meth delivery. With the JB4 safety systems Im happy to move into meth as a fuel delivery device as well as cooling. I limit boost through 1st and second, 10lb then 17lb then 3rd gear gets the full 25lb onwards. Also, for shits and giggles, it has a 2 step installed, so conveniently I can build boost from a standstill, I can get to about 8lb. With flames out the back of course. Installed is a no lift shift, so just bang the clutch and change gear while holding the throttle down maintaining close to the boost you've just shifted from. I have installed anti-lag but havent set this part up yet. If I've 2 stepped anyone I'm sorry, kinda like a machine gun going off in your face. More so now the custom mild steel rear exhaust has been replaced with a stainless steel one. Had the car in for its cert finally at Fraser Cars Birkenhead via Scott. Mostly required lock washers on parts of the car that BMW didn't think needed lock washers. Annoying, but them the rules. Otherwise the information is with NZTA to approve and get the plate on. Early June, says NZTA are happy bar a bump steer test booked in for mid June. Will be fine as virtually stock 1M front end and offset wheels are used with spacers. The next plan is to install the Precision Raceworks Stage 4 low pressure fuel system (running three intank Walbro E85 pumps), independent & larger low pressure fuel supply/return lines, 6 x 750cc bosch injectors and port injection manifold spacer. This will allow a full E85 even E100 fuel in the main tank and likely the deactivation and sale of the meth system. Simply not needed with higher E85 content, if available. An ethanol sensor (Continental) will be installed in the fuel supply line which also gets integrated into the JB4 for complete fuel integration from E0 to E100. This should net about another 20-30kws without another turbo upgrade.......this fuel kit is due early July.....turbo's hmmmmmm.... Lastly, there are some MMP Stage 3 full TD04HL turbo's that Im eyeing up, which have seen 550 rear wheel kw's on full E85. Pushed, these are the limit of the stock N54 engine apparently, circa 900 crank hp. Incredible that its an open aluminium block with this level of strength. Who says 2JZ's are the strongest? Factory forged crank and miele pistons. N55 are definitely weaker engines. Not saying they are weak ok, just 'not as strong as N54's'. However, I cannot stress the amount of misery there is in changing the turbos out, the main reason Im potentially unlikely to do so again. Took close to a week to change out over weekends and nights in the rain, fuggin misery. E82 LCI Blackline taillights added late May '17 and LED bulb change out inside and at all exterior corners. Error free my arse! So its taken me about 2 years to build it in my driveway, bar the panel and paint. Its cost a fair bit less than a real 1M, minus all the mods. Im guessing currently 410-430kws at the rears going from similar/same tune N54's in Aus. It sort of drives like a combination of a lazy boy and a fast motorbike.

-

Just the 30ff codes? I changed every vacuum line. Not hard job. Many lines to leak from around solenoids. Replace with decent boost silicon line. Usually the issue