-

Content Count

619 -

Joined

-

Last visited

-

Days Won

14

Posts posted by LsBeema

-

-

-

On 4/27/2020 at 5:47 PM, richard said:looks ok to me

See what I mean..just "ok"...

-

-

18 hours ago, zero said:Beautiful!

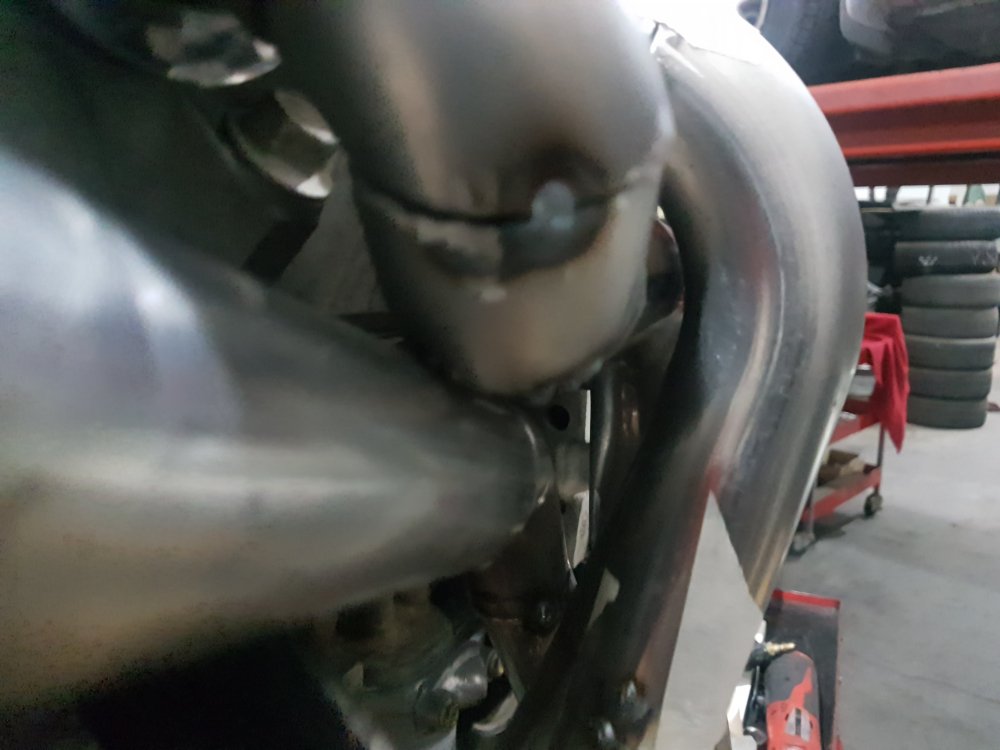

Thanks man. Spur of the moment setup pic..and doesnt she look might fine??. But...I aint impressedwith those headers. I should have made another set before doing these..to get my procedure thought about and planned. Also...I need a proper welding station, the machines feed at lower end either goes too low or high..variable knob is stoofed, a metal table with adequate clamps, much better lighting and a few more hours with a gun in my hand. The end product..is..OK...I will do some proper mandrel bent ones in december.

That photo shot says it all though..pleased with all the work up to this point.

Electronics, cats fitted and rear welded without muffler..to start up in 2 weeks..

-

3

3

-

-

-

NA STUFF THAT I FREAKIN HATE HEADERS??????????????????????????????

-

-

-

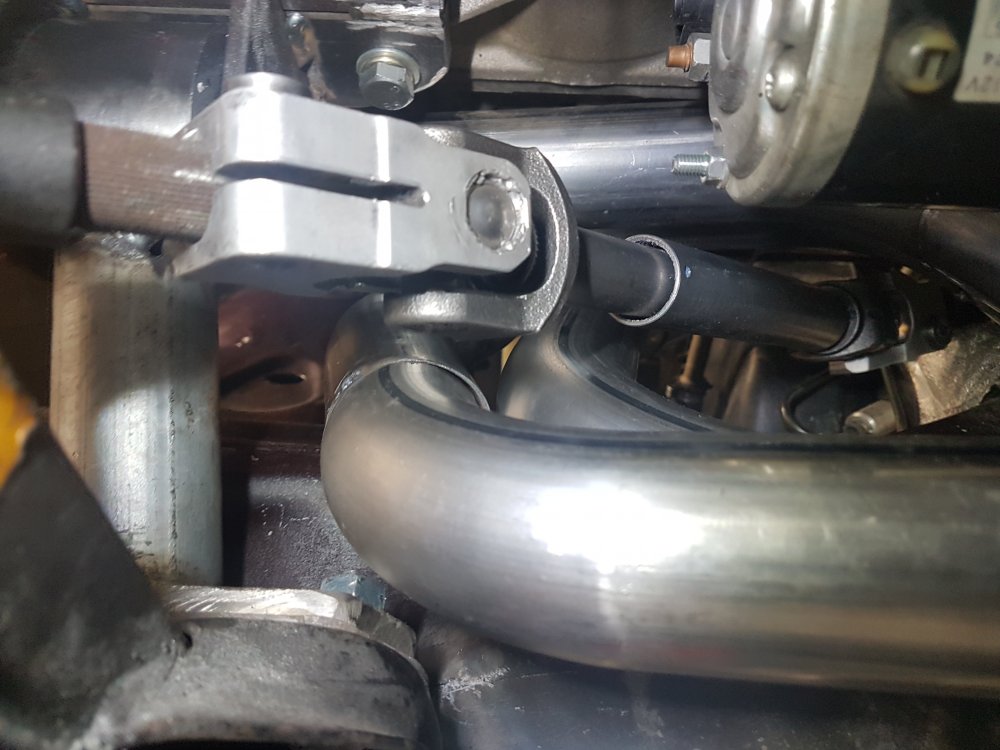

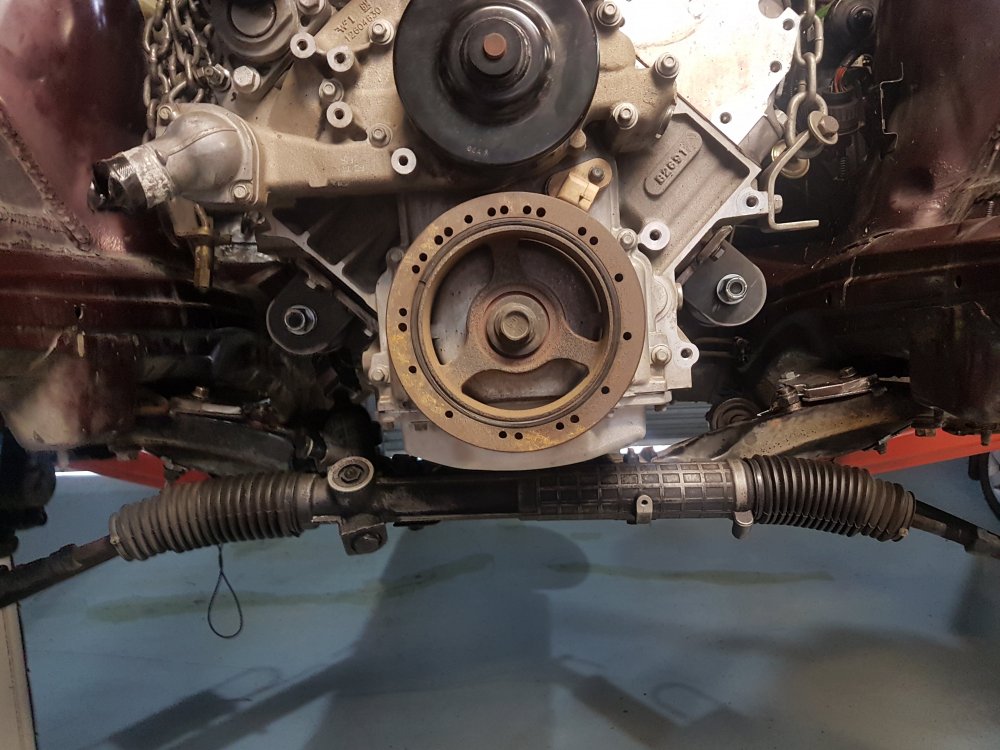

3 hours ago, Arron said:what steering linkage are you using?

Had one made up

-

-

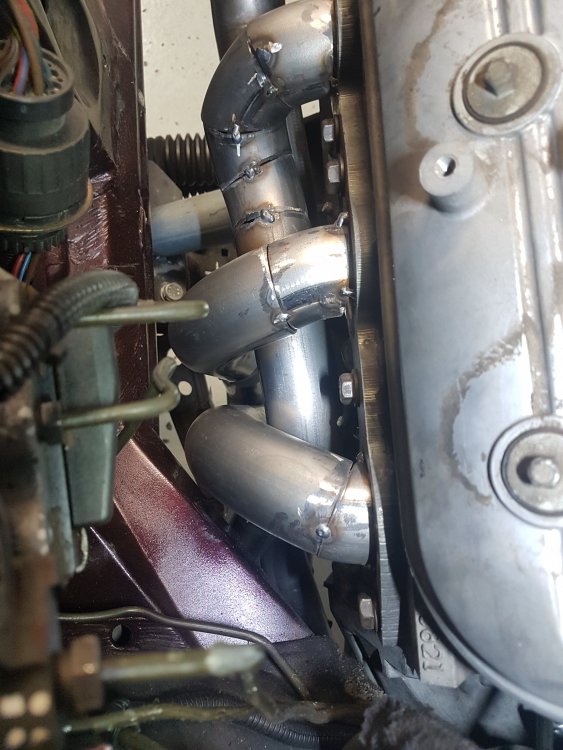

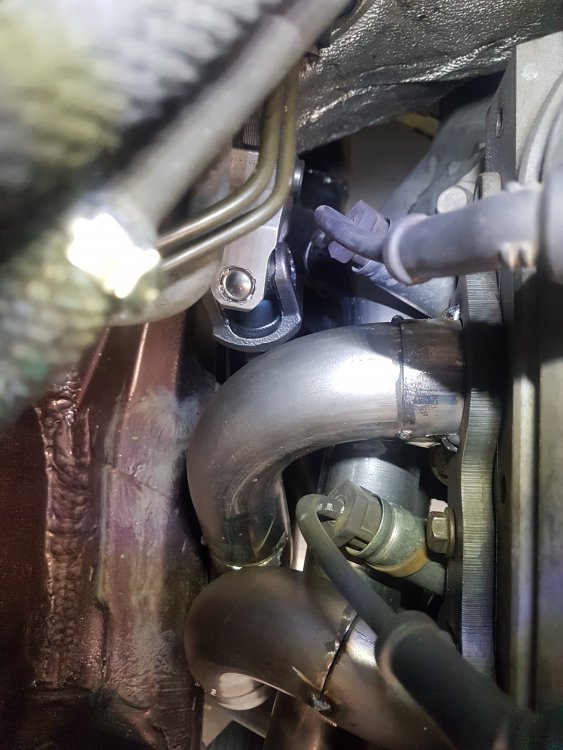

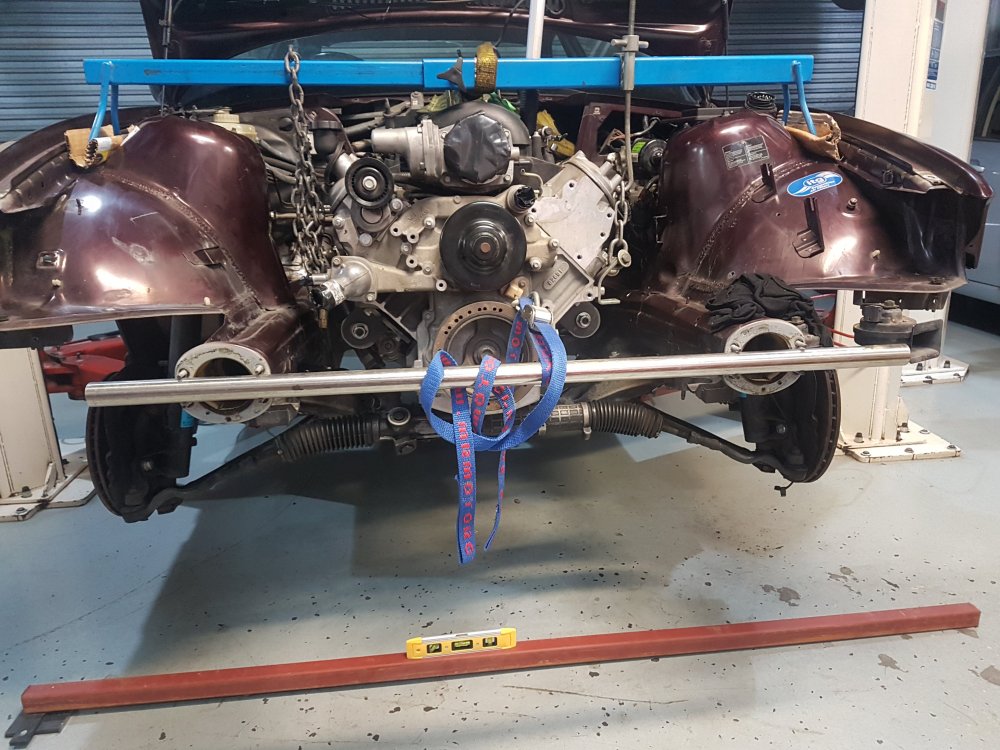

Much better...even with fitment..2 stage fitment...engine with headers and mounting plates on engine, then subframe...will try to bring no3 closer on the left so it can be a 1 stage process. ..if not..all good.

Gear lever also fits bang on...all these measurements with strings really work well ?

Planning exhaust setup. Will get cats in 2 weeks.

-

-

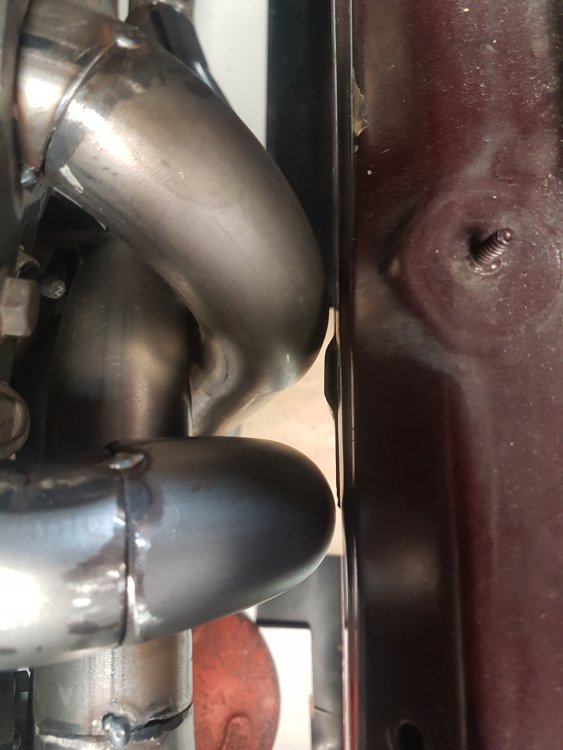

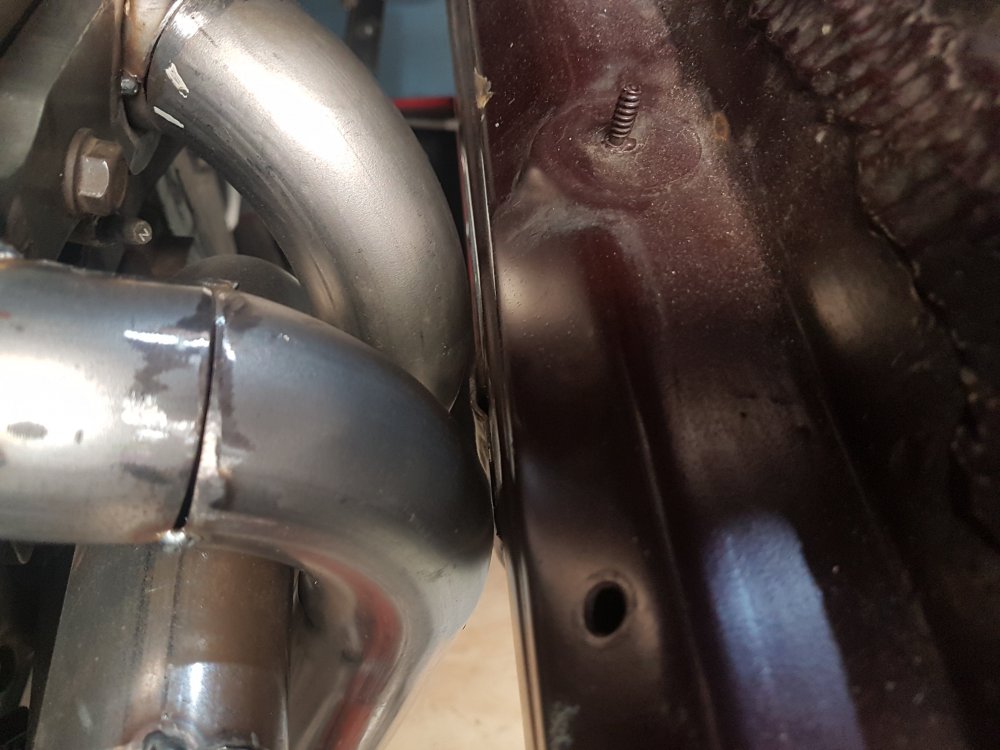

No2 pipe was abit to close to a head bolt and needed to shift it in order to get more clearance for pushing no 3 an 4 closer to the engine...and tidied that bend out. I want try to make it so that I can remove and install with the headers and subframe still attached to engine...they were abit wide.....or else has to be a 4 stage process..., subframe, mounting brakets to engine, headers then engine and box out..stuf that.. let me try. Got the left side about 12 - 13 mm closer...lets see on the right. Headers looked like they were about 20-25mm to wide..

Sourced out .8 mm mig wire.

Getting the hang of these headers stage brrus..kinda like it...the hardest part of this build as I said.

-

2

2

-

-

-

14 hours ago, Michael. said:Oh yea...similar ay. Nah man..I did abit of research...and planned as I went. Seems like I was on thr right track...but I should of made a few changes...annnyway..

-

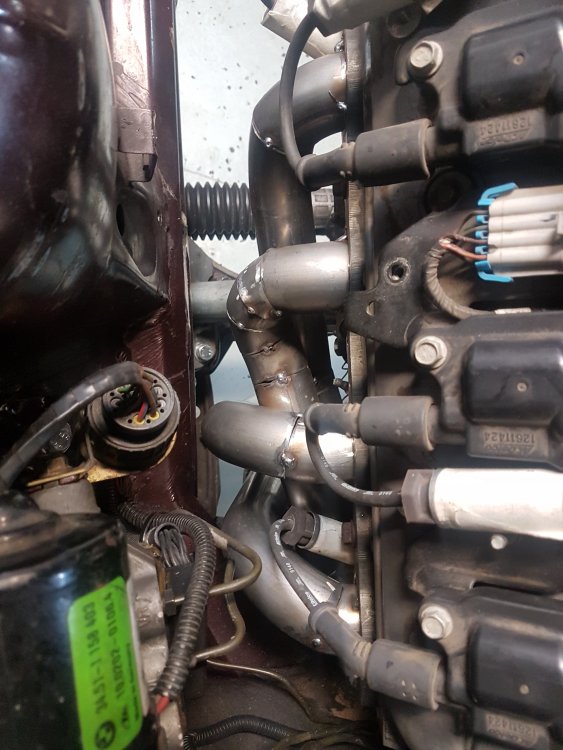

Toight man!! A few changes...but nothing major. NOT BAD AT ALL!!??...first time fabricating headers with a drop saw, an angle grinder, less bends and to trying to make them as equal lenght as can be done...no 4 on right 10-15 too short..F! ...the rest close ...

Now to weld the muddhas, without them warping. ...?some will be done on engine and will make a JIG with stoppers....

Also gear lever fault....pivot arm touches gearbox cos I had to shorten lever mount and shaftby 65 mm...supposed to be 80....she'll just sit 15 mm more to the rear...ot was a HARD descision to make...?

-

4

4

-

-

-

-

-

Limited with machinery..??...annnyway...job done.

-

-

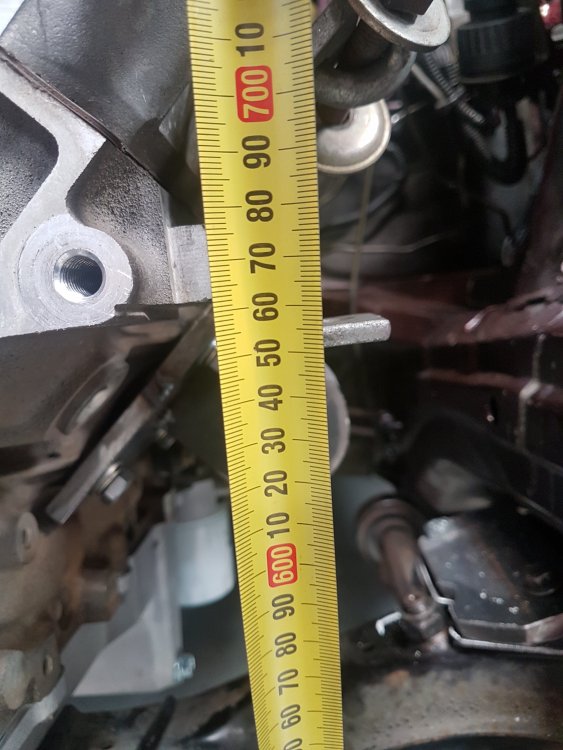

Took some time to square her up..hard holding phone with correct measurements but shes to the mm....pathetic..I know..should have been to 0.1mm??.

Will get my buddy to final whos a welder...mine arent that bad...but ay...lets get it done right. Now for the gearbox mount.

Placed the e60 diff again close to the subframe to plan out procedure...and yep...just ike the headers....good fun times await???

-

2

2

-

-

3 hours ago, M3AN said:Look at that, made to fit! ?

Thanks man. Its a first time for me doing a transplant of this capacity.....six blardee litres of capacity??. Nah but straight up...its all new to me.

-

3

3

-

-

Muffler and heat shield

in Engineering/Fabrication

Posted · Report reply

Redline dont got any homs...my cats from them...more resonator/mufflers..

With the heat shields need to stick them both sides...quite alot..any racing dude says stainless sheet...still deciding man..

Yep..ceramic ..defs