-

Content Count

506 -

Joined

-

Last visited

Posts posted by MLM

-

-

Fabric weight is not important, stretch is what you after to allow you to get arround the corners without wrinkles. A bit of thickness dosnt hurt to cover any blemishes but a dense material wont help. Hope that makes sense.

i think the description of mine was a knit like sweatshirt fabric. Sounds unapealing but worked well.

if you want black the fabric i used comes in black too.

-

Mine cost about $120 DIY equal cost glue and fabric. Its in my E36 project car so im not trying to achieve 100% OEM look but you would need to be a BMW geek to notice as its looks like it was a factory installation. I prefer the sloghtly darker grey as its a closer match to the dash than the factory grey anyway.

-

Used a ados f2 high strength spray. About one and a half cans including pillars and a sealing coat on the head liner. Sill not cheap i think its £25 a can. Used the same on my parents one about 6 years ago and its still holding well

-

Sounds about right. I did my compact the same way before i sold it and ended up clogging the brush and smearing brown gluey foam crap across the head lining backing which took ages to clean all the little bits up so it was good to go. The next time i tried a bit of flour which meant it all balled off nicely, no smearing, streaks or little bits hanging on. 3 minutes to clean off the glue instead of 30 minutes. Home baker BMW mod haha

-

Just did mine using a grey knit from spotlight which matches very well. Nice grey knit on one side and a white/grey fleece on the other. Its in the fleece section on card bails.

A tip to remove the oem glue is to sprinkle some baking flour on it before brushing off. Takes the stick out of it and stops it clogging your brush and smears. Just dust it all off then seal with one coat of spray glue before final glue and fabric

-

Top mount intercooler? Air to air or water to air? Was a bit surprised to read this as it seems a bit of a compromise (throttle response over power). Given more modern developments I would have thought throttle response would be achieved in other methods allowing that extra power gain, not that its lacking... Either way I'm sure the aftermarket option from someone wont be far behind.

Loving the looks, spotted one of the new m5's in the car park at work today and this looks to be along the same vain with added badass, looking forward to seeing one in the flesh

-

Give it a go, as 3pedals says its not that hard. I did one years ago for a 1500w 15 in a corolla, ended up hardly impacting on boot space and no plug or mold required. The way i did it was to buy rolls of paper masking tape and line the recess you are using taking advantage of all the nooks and crannies with a healthy perimeter. Then lay glass directly on top this. Once cured you can pull it out and trim the bucket shape you created. Takes some working and pulling to get it out but you still have some flex at this point

Then make up a mdf front panel on in my case just a ring and suspend it on dowels hot glued in place at the right position you want he sub to sit at. Then using stretchy fabric you can generate the organic shape from the ring back to the trimmed edges of the bucket. Some resin to stiffen the fabric then allows layers of fiberglass to go on top. Once cured the seam can be tackled from the inside through the sub ring. The final shape will be very strong. Finally sand and cover in the fabric/paint/carpet of your choice.

Edit: Instructions here http://www.instructables.com/id/How-to-Make-a-Fiberglass-Subwoofer-Box/#intro

-

Top shelf. My brother's team was the one with Turbo the snail. Said they had a blast.

Did Red Bull come and visit your build too (and bring free drinks)?

Turbo the snail was awesome, they did an awesome job on the bodywork. We had Red Bull visit us for an interview and sent us boxes of Red bull throughout. Must have been 250-300 bottles/cans sent to us in total. we also has 4 live come arround and various radio stations calling us. Our 15 minutes of fame!

Nice work! New Zealand is a small place, I know Andy from his Christchurch days playing football.

haha he seems to know alot of people. some of the other teams were ChCh based and he know them too..

-

1

1

-

-

Hi Chaps,

Thought I would share my minions and I effort for Red Bull Trolley derby with you all.

-

1

1

-

-

See the problem is I kind of agree with you, but when the water pump has been running for a period of time the charge its holding is 500millivolts. (0.5volts) When the car is stone cold and sitting for 12 hours its back to 30millvolts or 0.03 volts.

Only two things different. fluid is hot and under pressure (80-90 degrees c), The water pump has been running.

Why is it generating electricity when you run the motor? (engine head and block are both earthed and radiator is isolated)

I do understand that I probably have either a slightly acidic or alkaline ph level as the catalyst.

Again, i'm going to replace the radiator and fluid and data log it to show the differences.

Are both measurements with the motor runniing and the same electrical things running?

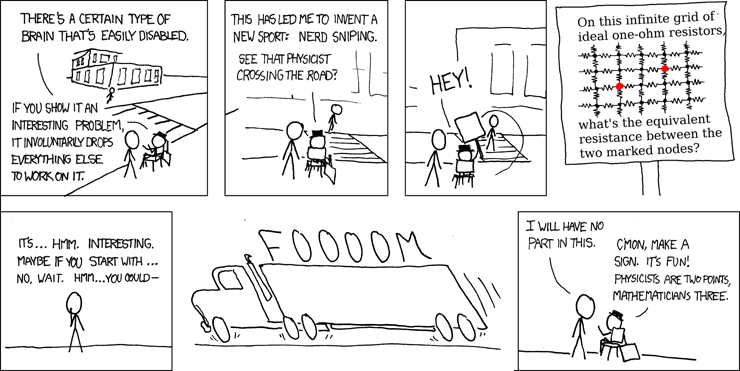

This prompted me to read arround a bit (got nerd sniped again) ant it seems there are two drivers, galvanic corrosion potential defference and electrical loss in the system. The potential difference of iron to ally is about 0.05-0.1mv. While temp and flow effects this and may explain the .5V your seeing when hot, the test conditions are important too. Ie if the door was open and the interior light on for one measurement it may upset the result.

Sounds like your going to log voltage on a warming car which is excellent and should reveal alot.

-

-

To add to the confusion

My understanding is:

Flashpoint is the temperature at which a volitile liquid reaches a concentration which can be ignited which is measured at 1 ATM.

The temperature at which liquid becomes a gas is the boiling point measured at 1 ATM.

-

My 2c

Flash point is the temperature required to support a vapor pressure which will ignite with an ignition source. If the atmospheric pressure drops the ability for the 'fuel' to boil off increases (increase vapour pressure) . Seeing as the air is less dense at a lower atmospheric pressures you will approach the required air fuel ratio (flash point) sooner for a given temperature. There would be limits to this such as a very low atmospheric pressure (zero or just above) there would not be enough air to support ignition or said another way the ratio of fuel exceeds the air available it wont burn.

If this is part of an exam question your studying i would do some more reading.

-

HB dude

-

Have a peruse around here http://www.m42club.com/forum/index.php lots of disussion on chips etc. Search is your friend.

-

Go to Gilmours, or some other commercial food supplier - buy enough white vinegar to fill the block a couple of times (or submerge it). Leave to to sit for a month or so

It gently removes rust with destroying anything important (take off the aluminium bits though

It gently removes rust with destroying anything important (take off the aluminium bits though

straight white vinegar has been used in running Model A Fords as a cooling system cleaner a number of times. I know of a guy who runs it for a month, INSTEAD of coolant/water to clean it out, then flushes and refill with coolant. A lot of model A guys run with out coolant, so the rust can be nasty sometimes.

White Vinegar eh? really? Well i have some white vinegar in the cupboard and I have no idea what i bought it for so might as well give it a go...

Well after two days with a splash of vinegar in the block i must say im a convert! Allen you legend!

You can see the tide line where the vinegar was sat and the grey iron below and the scaly crud above.

Dont mind me, im off to get more vinegar...

-

1

1

-

-

End of 2010. The bung is a non issue for me as the rad is easy to drain and remove.

-

Have a redline jobbie too and its ok. Only complaint is the lower drain valve is low quality brass which is chalky so replace before you install. Mine has broken the tip off. Hasn't effected the function overall. For the dollars in happy with it. Suspect china made.

-

Have started to tear down my spare engine. I bought it a few years back as an impulse buy off trade me as it was going cheap enough. Since then i have hauled it arround eveywhere and has served as a jig when building my exhaust manifold. My intentions..? Dont know yet. Having a learn and a play for hopefully not to many $$. Got some ideas but as always will be doing as much as posible myself as thats where i get the enjoyment.

Anyway some pics..

Head off, looks ok. Its the 6mm valve stem variety so should flow a bit better than the 7mm type.

CC'ed #1 chamber at 34.5 cc

Did the same for a piston as well at 7.4 cc

Used a syringe to inject water accuratly + a set of sensitive scales to verify, those bad boys can detect the air pressure created by waving your hand above them. According to my calcs this gives a 9:9ish compression ratio which is a touch down from the advertised 10:1

Block looks ok, some rust scale in the water jacket which will need cleaning out somehow. Factory crosshatching still visable

Finally cleaned and painted all the covers etc.

I have some ideas about using another maufactures pistons for a high compression overbore but need to research a bit more first.

-

Hey Rob,

Car looks mint! Finally seeing the light of Bm's eh...

Matt

-

After 2 cans of spray glue and a trip to spotlight i have re trimmed the headlining in the Ti including sunroof panel.

-

-

Yup any colour can be done in powdercoat inc metalics I believe. I chose black which had the benifit of being common and could be batched in with other jobs saving a few $$. Specific colours may incur a setup fee as the gun needs cleaning for the new colour etc.

-

+1

Powdercoat is a bit thicker so can cover those minor imperfections better than paint. I did my wheels in PC an am happy with the end result.

riddle me this on a sunday arvo

in Off-Topic

Posted · Report reply