-

Content Count

617 -

Joined

-

Last visited

-

Days Won

14

Posts posted by LsBeema

-

-

Guys the car is such a smooth/vicious/calm and CRAZY moster. The instant torque from the 6.0ltr to the stripped 36 is AMMMMMAZING. and the sounds one of the best 8s ive heard...not because I constructed the acoustic nature of this beast...ok...annnyway

Shes in the shop( HIGHSPEK) for the first time. Lowering the radiator by 20- 25 mm to fit a 4 inch intake and get her prept for the tune. Got some 17s for the rear to start with the real run of loosing/controlling the rear as what BMs were made for...

-

1

1

-

-

Hi guys. . and girls..and...yea...

Dony know if this is the right place or even if I can put this here. ...

I recently started up my own Workshop called HIGHSPEK in Carr road Mt Roskill Auckland.

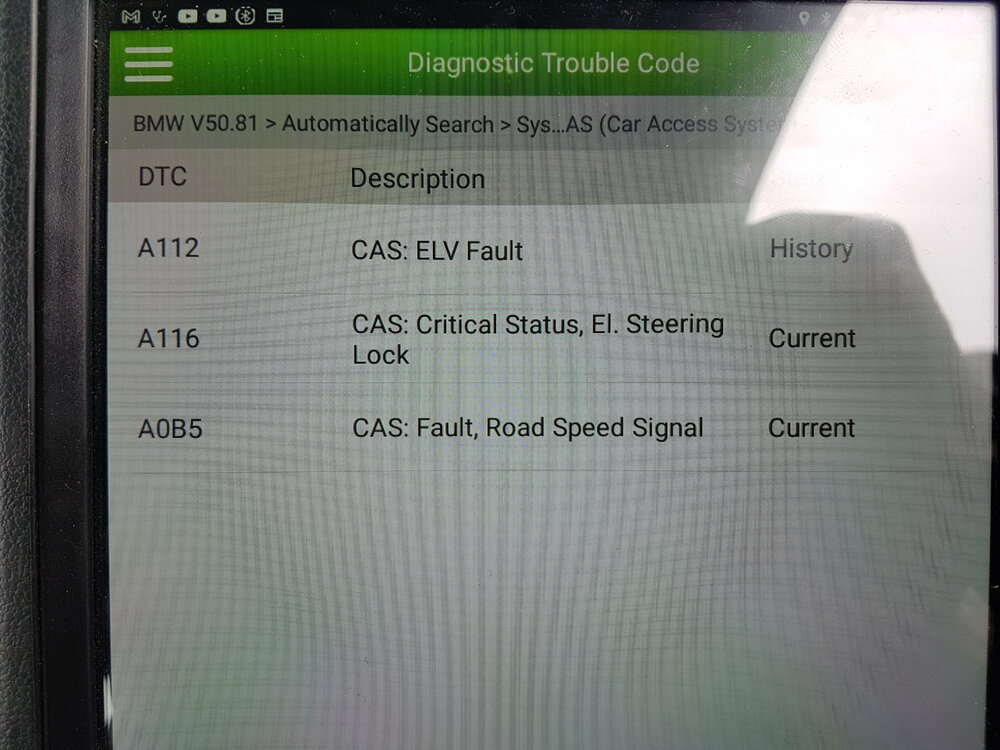

Just to let everyone know that Im still in setting up stage but I can do servicing and maintenance work, some repairs and Diagnosing with a Launch Scan tool.

And yes...that is how we spell "fulids" in SaKiwi standard😉

-

9

9

-

-

10 hours ago, Michael. said:Getting the driveshaft done is oddly satisfying as you now know you can now physically put the power down with the new engine. A very fun part of the build process sorting out such vital parts.

Hagree

-

1

1

-

-

On 12/20/2021 at 7:29 PM, Cement said:Yeeeaaauuuuuurrrp

Here are the bank 2 headers finish welded apart from the flanges. Not sure how I am going to rectify the distortion caused by the welding just yet ... a real bummer and something the experienced header builder would expect. Should have build and welded one or two sections as I went. Still, they look good in a picture

Here are the bank 2 headers finish welded apart from the flanges. Not sure how I am going to rectify the distortion caused by the welding just yet ... a real bummer and something the experienced header builder would expect. Should have build and welded one or two sections as I went. Still, they look good in a picture

Looking Toight an Tidy Mate!!!

-

1

1

-

-

-

-

On 10/31/2021 at 9:16 AM, Cement said:Headers are a lot of work it turns out, who would have thought

First tube is complete apart from being finish welded at least ... I'm 'ok' with the result. The major learning is that next time I'd probably go with pie cuts instead of the tight 1D donuts. The donuts are only welded one side and if you close the gap you end up with an under sized diameter. So I will have a whole lot of little gaps to fill in at the end 😕 When i get to the tubes for bank 2 it will get a lot harder as the tubes are almost completely made of 1D sections 😭

First tube is complete apart from being finish welded at least ... I'm 'ok' with the result. The major learning is that next time I'd probably go with pie cuts instead of the tight 1D donuts. The donuts are only welded one side and if you close the gap you end up with an under sized diameter. So I will have a whole lot of little gaps to fill in at the end 😕 When i get to the tubes for bank 2 it will get a lot harder as the tubes are almost completely made of 1D sections 😭

Anyhow I will be cutting segments for pipe 3 today and hopefully getting some bits tacked together. Pics of where things are at ...

Looking sharp brru

-

On 10/22/2021 at 10:16 AM, jon dee said:REV IT UP !!!!! 😉😀😎

Was built for idle. Thats all it takes to move 1300 kgs with 6.0ltrs of torque homs. Drives AMAZING !! oook on topic. ...yea man...will do differnece vid.

-

-

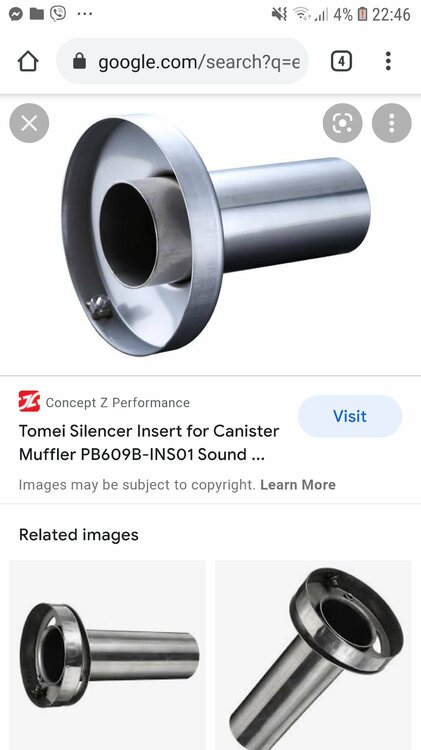

SAY HELLO TOO MY LITTLE FRIEND!....any.one watched scarface...

Sooo Pleased!! Will chuck a tad of fibre in the center but allllll good. Wife and neighbours will be at peace with no windows and neighbours neighbours with no teeth rattling. 😎

Will take out one more looop of the spring to make it abit toighter ayy

Earphones..

-

Not a great vid. But pleased agin with the design. Will test the acoustics at the place of sleep on whether fibre is needed...bit satisfied as is.

-

10 hours ago, Twistee said:So which part silences the wife? I'll take a set when you crack the solution. 😁

Haha... a few if not all of thee 5 LOVE languages works for me and many-o-maneth around thee worldeth my brrueth💘❤💓💕💖=🤗😘😍 which wil get you 🤐

-

56 minutes ago, Arron said:Not sure if you are aware or not, but the tr6060 runs ATF rather than gearbox oil and don’t seem to like if if you don’t run the atf!

Did heaps of reserch brru...also was advised by a few Holdeners on the justcommodores forum.

-

51 minutes ago, jon dee said:I'm having a little trouble working out what part the plain steel (silver) tube plays in this assembly ? The black painted items appear to be resonators/hotdog mufflers with one end cut off, and if the outside of the resonator slips inside the outlet of your main muffler, then they will form a significant restriction to flow.

If the non-perforated steel pipe is placed inside the louvred pipe then you will pretty much nullify the sound absorbing potential of the hotdog while providing a straight through path for exhaust (and sound) exiting the main muffler. The purpose of perforated tubing is to allow sound to pass out of the tube into the sound absorbing packing, and you would be preventing that from happening.

From the title of this post I guess that you are looking to make a removable assembly that you can use around and remove when at the track. I applaud your consideration

I would suggest that you might get a better result if you omit the inner non-perforated pipe and make some kind of cone to feed exhaust gases smoothly into the louvered section. If possible re-pack the hotdog with fibreglass exhaust mat, and clamp the extensions onto the main muffler outlets.

I would suggest that you might get a better result if you omit the inner non-perforated pipe and make some kind of cone to feed exhaust gases smoothly into the louvered section. If possible re-pack the hotdog with fibreglass exhaust mat, and clamp the extensions onto the main muffler outlets.

Definitely not a performance modification, but combined with a light right foot it may be enough to keep your neighbours happy.

Cheers...

Lovoured part is directional(as you know) and spiral. You can even see through at certain angles some fumes could/would get through while being absorbed. I had 2 18 inch ones before this free flowing muffler which didnt do jack, while testing if it could make a difference for the 2nd cert inspection. The aim is to make it adaptable mainly for my driveway at home so if I leave early in the am or come back late at night the people in the pther street doesnt get any hernias.

Lets test the concept for the flow of gases of my version of a removable silencer that which the center pipe is long enough for exhaust gases not to bounce back and escape, but to be absorbed...well thats the concept...lest see homs..😎

Could of bought 2 of those for $35+- .

Had these laying around at 25 ea. So decided to do things my way...

-

-

-

-

Awrrite now.... no mucking around chain dragging lockdown slow Vq speed...GET THIS DONE!!🤣🤣

-

1

1

-

-

-

-

-

On 10/3/2021 at 8:31 PM, thorburn said:Any reason for not going with a round driveshaft hoop?

From an Engineering/strenght spec..im sure a circular design would confine a loose driveshaft much better..

But Picasso was also questioned..."WHY"...

I just did it my way...cos why must one follow... also to make it look more factory brru.😎

-

-

8 hours ago, Michael. said:Love some Holden action.

Impressive results, looks like a fun cost effective build!

What model engine spec is this?

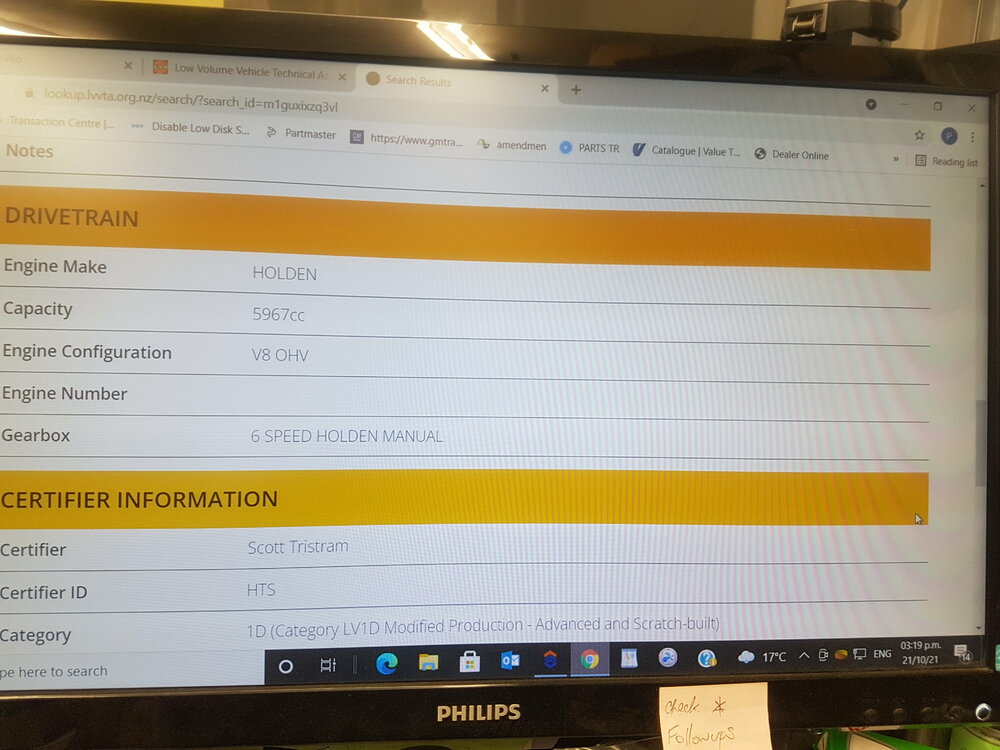

Its a L76. Which is like mine...a Ls2 6.0 ltr bottom ends with Ls3 6.0ltr heads. The L76 come out with Afm cam and lifters to cut out 4 cyl on motorway runs. We did the Afm delete with the cam upgrade and milling the heads giving 517hp. The exhaust system on the 76 is stock HSv headers, cats into dual 2 1/4 inch all the way. Mines long tube close to equal lenght with dual 3 inch. .. porting the heads, bigger thtottle body, maybe ITBS or a diff manifold...and lets see..if I ever do that😎.

Cam and Afm delete kit, milling heads, remap and tune...for 260 kw to 380 here.🤗🤗 We are so pleased.

HIGHSPEK has begun....

in News

Posted · Report reply

I got a guy.

022 689 5884.