Leaderboard

Popular Content

Showing content with the highest reputation on 04/04/25 in all areas

-

3 pointsLong time no see. This car will be for sale soon, I'll list it on BS before TM, it's a fantastic platform with all the upgrades and a ripe candidate for a manual swap if you're so inclined. Why? This:

-

3 pointsWhat on earth.. I want a Convertible, but it must be a boring color. I want it to look sporty, but get great economy. But be spicy enough that it is still fast, but make it 4WD so it's safe. I like the base model steering wheel so add that....

-

3 points

-

2 pointsSurprised it hasn’t got a tow-bar on it so it can haul a boat / caravan / trailer. It is truly eye-opening how many models are offered across all the markets in the world, and options. We only see a very small percentage of them here in NZ.

-

2 pointsThe towbar saga. One feature that the car came with was a folding electric towbar which seems a bit excessive and sure has some 'wank factor'. However, being able to fold the towbar away at the click of a button is quite handy. It tucks away completely and has no impact on the look of the car when not in use. The only gripe I have with the towbar is the complete lack of a feature we use quite commonly in NZ, a 1-5/8" towball. Quite infuriating because you only ever find that out as you go to hook up a trailer. I should've thought about it really, being a euro of course its going to have a 50mm towball. Eitherway it needs to be fixed. I had two options to start with, either take a grinder to it, using a whole bunch of templates, measuring and loads of patience. Or, pay someone to machine it down for me. The first option really is a sh*t idea, however this appealed to the side of me that really doesn't like paying for the services of other people when I know I could have a go at it myself. The cost of machining is around ~$500, which isn't too bad in the scheme of things, still hurts though. The other issue with these two options is that I would still be stuck with only one of the two towball options (although 50mm is uncommon it still pops up just enough to be annoyed you don't have both options). I removed the towbar from the car and had a good clean behind the bumper while I was there, this car used to live up a gravel driveway so everything has a dusty coating. I removed the electric actuator and unbolted the ball and arm from the bar. I knew this was going to be a longer process so I put the bumper back on and left it for a few weeks, which I'm glad I did. I was yarning away to my mate Tony who came up with the idea of using a "convert a ball" style setup. Its essentially a 1" spigot which the balls slot onto and a pin slides across to lock it into place. This is the perfect solution as it is much easier to create a cylinder with a grinder than it is to make a sphere, and it also means I'll have both towball options. I borrowed Tony's towball setup off his Audi and I got to work modifying mine. My plan of attack was as follows: mark a centreline on the ball and slice off a plane parallel to that, with a flat surface I then create an opposing plane on the otherside of the ball. With some flat surfaces to work with I can chop it back into a square section. At this point it would be wise to drill the cross pin hole. Chopping off the corners until a 32 sided shape remains gives an approximate cylinder with hopefully a diameter of ~25.60mm. Then rounding it out would make it into a circle and taking just slightly more off would bring it down to 25.40mm in diameter. To get all this done I used a hacksaw, angle grinder with a 60grit sanding disk, some emery cloth and a file to remove material, for measurement: a digital caliper, ruler, various markers and a decent eye. After a solid few afternoons slaving away I ended up with a pretty decent result. The fit is better than the "convert a ball" spigot so pretty stoked with that. The next three afternoons involved me absolutely wasting my time while I tried to figure out why the mechanism wouldn't release when clicking the button. Turns out you have to reset the actuator by holding down the button for 5 seconds. Got there in the end. While I was at it I lubed up the swing mechanism with some fresh grease and replaced the grade 8.8 mounting bolts for peace of mind. Overall a successful project, glad to have it sorted.

-

1 pointTorrential rain yesterday and today so I can't do any work on my retaining wall at home. Got round to a little job I've been wanting to do for a while. The trim around the SMG shifter boot makes an annoying plastic on plastic creak sometimes when shifting, which isn't particularly pleasant from a driving experience point of view. Today I took the trim apart and used some tesa tape to insulate the clips and mating surfaces. I also gave everything a good clean while I had it apart. Put it back together and the squeaks are completely gone (unless I press very hard directly on the plastic trim), shifting is now a satisfying mechanical click, rather than the annoying creaking sound it could be before.

-

1 pointZe Germans were pretty organised when it came to the holes and they are in the same place for most of the E30 spoilers. As SJ says the SE Lip and bigger Tech I lip both fit in the same holes. The SE is fairly common and can be got quite cheap, the Tech I is rare and expensive.

-

1 pointIt's back. Now on Sunday Drive. Love this car. https://www.trademe.co.nz/a/motors/cars/bmw/540i/listing/5249534993

-

1 pointSE spoiler or tech 1 spoiler will bolt straight into those holes bud!

-

1 pointProbably a stupid question, but which spoiler goes on that boot lid? My e30 has the exact same holes, so may be easiest to just cover them with a spoiler

-

1 pointFitted my new spoiler… Paid a pretty penny for it from Alpina to replace my (probably fitted at dealer when new) M3 item, only to find that the sedan spoiler is the same as coupe and I could have used the one I found on a Jap import 318iS coupe a couple of years back! Ah well. Will probably replace the boot with a non-spoiler one and have it repainted, as the holes are very different to the M3 ones.

-

1 pointCame off the mountain bike 1 week ago, to the hour, at Redwoods in Vegas down a grade 5. f**ked up a drop, ended up going over the bars and headfirst into the ground. Full face helmet exploded, I remember sliding along dirt and tasting it with my body ragdolling behind my neck. It wasn't a nice feeling. Once came to a stop was on my back and staring up at the tree canopy. Can I feel my toes? Yes. Thanks f**k. Can I move my fingers? Yes. Thank f**k. Can I Breathe.... Yesss... THONK(Owwww). Can I get up? No. Things are crunchy. Rescue medics came pretty quick and stabilised my spine, was thrown onto a stretcher and 6 people lifted my ass out of the forrest and into a ute. Ute met ambulance who took me to Rotorua A&E. Xrays and CT scans, quickly reviewed. Multiple broken vertebrae, sternum is broken in multiple places (I over heard the CT tech says "f**k I bet that stings" ). Due to how smashed sternum is, and the amount of force required to do it, they were worried that my squishy important innards took a beating. so got 2x ECGs which showed normal cardio activity. Rotorua then ordered my ass a helicopter, which flew me (wrapped up like a burrito) to middlemore emergency (who have the best spinal unit in country). 4 more X-rays, two more CTs, cardio ultrasounds and ECGs. Alll damage is structural! I have broken 4 vertebrae (C1, T5, T6, T7... so essentially i folded into a staple shape....) No neurological damage, no spinal damage, no cardio damage. 4 days after nearly ending myself I became vertical for first time and got to see something other than ceilings.. catheter then comes out (which took 3 people and me biting on a rolled up towel, the f**ken pain was unreal). The next day Im walking around. I can feed myself. I can wash myself. I can go to the toilet. 7 days after coming within millimeters of the edge, I've been discharged and am at home with my family. I owe a lot to the rescue and medical professionals, and to the engineer who designed my helmet. Will be at least 6 weeks until am out of brace, and then can think about driving again... but Im pretty sure I just won the lottery.

-

1 pointThere was another diamondschwartz import manual one the E34 facebook group recently which i think sold for 12k asking My valuation would be 20-25k in this market based on the info. A similar 540is to this sold for 18k pre-covid.

-

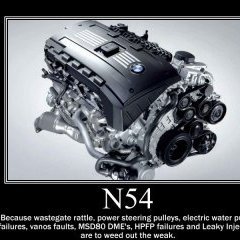

1 pointI've built this 135i into a 1M over the winter in my driveway. It has BMW factory 1M steel panels all bought new frpm BMW NZ. Changed out panels and rear guards using BMW factory repair methods, using BMW rivets and special rivet machine and epoxy. Runs all the right M3 parts, subframes, big d. shafts and LSD diff but has plenty of upgrades too. Basically take the entire 1M parts list and buy them and swap them to the 135i. I haven't worried about inside so much. Full bolt ons, 9" intercooler, intakes, catless, 3" exhaust, RB Next Gen turbos, cold and hot side intake pipes upgraded and modified, MHD E85 flash, JB4 G5 Iso, making around 650hp with meth and running E30. Stage 2 LPFP. I't runs 27lb boost. Meth installed over the xmas break and controlled via the JB4. KW V3 coilovers, vorshlag top camber castor plates. AP Radi-Cal brake kit all round. H&R sway bars, adjustable endlinks, Harder subframe bushes and most rubber parts changed out for Urethanes. 245/35/19, 295/30/19s. Manual 6spd. Upgraded clutch & plate from 550i. Carbon CSL boot lid. I've done all the work apart from the panel and paint in my driveway, head torch on my head, in the rain, frequently at night. Been a long slog, but worth it. Daily driver. According to BMW NZ this is NZ's first 1M clone. The way I treat cars and drive them, I couldn't/wouldn't modify a real 1M, nor could I afford one.