-

Content Count

1889 -

Joined

-

Last visited

-

Days Won

129

Posts posted by Sammo

-

-

-

9 hours ago, E30 325i Rag-Top said:I think a couple of Auckland E30 owners took advantage of the situation to do a few skids… @Sammo

Fingers crossed it didn’t end badly for any, there was certainly a lot of crazy sh*t going down here last night!

Don't worry, she was safe and sound by the time it got gnarly!

-

5

5

-

-

Much better photos though!

-

Would be looking at a manual M235i.

Or a manual E82 135i manual / DCT with more to spend on mods etc

-

1 hour ago, C-130 Hercules said:What is this nonsense having to apply for an overlap RUC if your current one takes you beyond 01 Feb?! Can they come up with nothing better?

Is the discount ending 1 Feb?

I better get cracking if so!

-

Nice man, what did you use to patch the dash?

I have a fantastic matte clear finish product used for refinishing leather that leaves a great silky matte soft finish - want to use it on my dash if I ever re-do it at some point (only one crack at this point).

-

A big thank you to @Cement for sorting the exhaust leak for me today and taking me for a quick blat in the mighty (edition 1 of 1?) VQ37 E46 💪🏽

One less thing on the to-do list!

-

13

13

-

1

1

-

-

-

Curbed the missus' front left wheel on the F31.... she had already curbed it so no real drama but have lost my right to moan about her curbing!

Is there any way to repair machined metal finished wheels?

-

On 10/23/2022 at 3:02 PM, dubman said:Was the motor out to weld in this area? got some rust there too (under glovebox / firewall skin) that I've done a temp patch on but will need doing properly eventually...

-

This thing is getting so dialled in!

-

1

1

-

-

I think you made a great choice - F31 is a great base and 328i is a good mix of performance and economy.

I added wireless Carplay / Android Auto to mine which is a cost effective upgrade to bring it into the current decade too.

-

1

1

-

-

20 hours ago, Cement said:Have a welder at home if you want to fix the leak @Sammo, I think we are in the same sort of area.

That would be amazing thank you!

-

1 hour ago, E30 325i Rag-Top said:Could be a good excuse to change back to the original 325i exhaust system twin pipes, but would be $$$s.

Easy fix with a bit of a grind out and a blob of weld.

Aside from a bit of drone under low load at 1500-2000 (rarely experienced due to gearing) I’m very happy with the current sound.

This is the only part where it goes to a single pipe - presumably adapted to fit the one in two out Remus muffler.

-

1

1

-

-

2 minutes ago, Eagle said:Least you know where you at now

Damage from jacking without wood etc block?. Yeah it appears to be. You could probably hear, feel or smell it but could also spray bottle some water to confirm.

Correct again! Can also detect a tiny rasp / buzz at 3k that was not there previously.

One step forward, two steps back haha

-

1

1

-

-

On 1/4/2023 at 4:18 PM, Eagle said:Did you have any vibrations before hand? What are brand are the mounts? Ive had new OEM engine mounts cause vibrations that weren't there previously, so its possible.

Is transmission crossmember parallel and not at a poor angle? Should sit so the driveshaft looks straight from the transmission to the rear looking at it from the bottom. I dont remember what the E30 crossmember looks like but there is usually some adjustment.

I guess its possible you upset the flex disc depending on how you jacked it, if its old it may of stretched\cracked. I usually jack up the transmission from the rear just in front of the cross member with some wood, just so its just touching, undo the bolts then it lower it down to get access.

Transmission nuts are 43-48nm according to E30 Bentley, wouldn't be easy the do that with a standard ring spanner under the car.

Maybe a bit of a pita if you re-install the old mounts, maybe one set at a time and re-test, at least it will eliminate the new stuff (once all the other checks are done)

Thanks man - summoned up the energy to try again today and you were correct on two counts:

I had slightly misaligned the cross member (took off one side to squeeze in the new mount) and noticed a quirk (defect?) with the new mounts:

On the side where it mounts to the cross member the metal base was clearly convex (pictures show it below but quite obvious IRL) meaning it wouldn’t sit flush on the cross member and would also try to spin on its base when I tried torquing the lower nuts.

Put the old mounts back in and while I can still detect a slight vibration at 1250 and 2000, this is only in neutral with the clutch out and car stationary - it goes away as soon as the clutch is depressed and is not detectable at all while driving.

I suspect it may be an existing minor clutch component vibration which was made more obvious with the new mounts and my poor install effort.

I did find / create another side issue though - replaced my rear exhaust hanger bushing (rubber figure 8 thing) and think I’ve created a little exhaust leak wrestling with the exhaust to get the rubber on 😑 I assume an exhaust leak looks like this:

-

1

1

-

-

Changed out my engine mounts and transmission mounts yesterday (with OEM rubber) and all seemed to go well but on my test drive had a strong vibration at low rpm.Got under car again and saw the exhaust bracket bolts where it connects to trans were loose (presumably from me jacking up the tranny to change the mounts) - this only helped but didn’t solve the problem though…Still have a mild vibration right under my drivers seat at around 1.25k and 2k rpm (it goes away if clutch is depressed).I re-checked the nuts and believe I installed the transmission mounts correctly - only thing is I used different top nuts to what was on beforehand (I used a flange nut with washer as the ones that were on it were some kind of one piece design and partially rounded.I did not torque the top nuts as I could only fit a little 13mm wrench on them so just tightened as much as I could.Any thoughts? I assume as it goes away with the clutch disengaged it indicates it’s driveline related, most likely something I did wrong installing the new mounts... the DIY I followed was similar to the engine mount process - i.e. jack up slowly until you can carefully remove and replace mounts - wondering if I should have removed the brace instead to minimise lifting the tranmission? -

-

On 12/26/2022 at 8:30 PM, Neil McCauley said:Might have been orange peel out of the gun that required wet sanding?

I'd be wanting pictures of the kit completely off the car from anyone advertising an mt2 with a full respray.

You’re making me nervous about when my kit comes off for rust / paint next year!

-

1

1

-

-

38 minutes ago, Bandit said:Its not re registered at all. The registration is continuous, with new plates issued on 22 November.

You're absolutely right 😶

-

10 minutes ago, gjm said:Aye.

It'd need a lot of paint and interior for a $25k uplift, but I appreciate it's a 'try price' as much as anything else.Especially being a manual swapped LHD when a gorgeous and overhauled bona fide M325i is currenrlt for sale at $43k

-

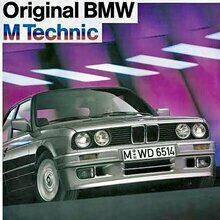

18 minutes ago, gjm said:If I was to say I knew of a "Genuine & Rare 1990 Facelift MTEC 2 BMW Coupe for sale $49,990", had paint etc, but has a different rego...?

Same vin - not sure why the plates were swapped though

-

1

1

-

-

11 minutes ago, gjm said:I saw this. Was it another "reluctant sale" change-of-plans listing?

I think it was more speculative - has had a fair bit of work done since though - paint / uphostery etc

-

On 10/27/2022 at 5:46 PM, Sammo said:https://www.trademe.co.nz/a/motors/cars/bmw/325i/listing/3834747098

Very interesting - an Auto LHD JDM Mtechnic 2 converted to manual here.

I am jealous of those sill covers!

This one went for $23,500 in the end - up for sale now for $49,999

-

1

1

-

What are these worth? Full Black Aluminium Cube Trim Set For E46 Cube

in General Discussion

Posted · Report reply

Think I sold mine for $150, replaced with the rarer Piano black which I paid $300 for.

Mine were not as nice, but probably just keep them unless you get good money.